BB Tools

BB Micro Drill (0.3mm~3.99mm) D=4mm

BB Micro Drill (0.3mm~3.99mm) D=4mm

No se pudo cargar la disponibilidad de retiro

Share

| Name:BB Micro Drill Material:Micro-grained carbde | |||||

| Number of flutes:2 Series:BB2055 | |||||

| Diameter of shank:4mm Application:For general purpose | |||||

|

|

Cuting diameter |

Shank diameter (D) |

Cuttlng length (L) |

Total length (OL) |

Angle | Tolerance |

| 0.3~0.5 | 4 | 4 | 50 | 118° | -0.005 |

| 0.51~0.99 | 4 | 6 | 50 | 118° | -0.005 |

| 1.01~1.49 | 4 | 8 | 50 | 118° | -0.005 |

| 1.51~1.99 | 4 | 10 | 50 | 118° | -0.005 |

| 1.0 | 4 | 11 | 50 | 118° | -0.005 |

| 1.1 | |||||

| 1.1 | |||||

| 1.2 | |||||

| 1.2 | |||||

| 1.25 | 4 | 12 | 50 | 118° | -0.005 |

| 1.3 | |||||

| 1.35 | |||||

| 1.4 | |||||

| 1.45 | |||||

| 1.5 | |||||

| 1.55 | |||||

| 1.6 | |||||

| 1.65 | |||||

| 1.7 | |||||

| 1.75 | |||||

| 1.8 | |||||

| 1.85 | |||||

| 1.9 | |||||

| 1.95 | |||||

| 2.01~2.49 | 4 | 12 | 50 | 118° | -0.005 |

| 1.95 | 4 | 15 | 50 | 118° | -0.005 |

| 2 | |||||

| 2.05 | |||||

| 2.1 | |||||

| 2.15 | |||||

| 2.2 | |||||

| 2.25 | |||||

| 2.3 | |||||

| 2.35 | |||||

| 2.4 | |||||

| 2.45 | |||||

| 2.5 | |||||

| 2.51~3.0 | 4 | 15 | 50 | 118° | -0.005 |

| 3.01~3.49 | 4 | 18 | 50 | 118° | -0.005 |

| 3.05 | 4 | 20 | 50 | 118° | -0.005 |

| 3.1 | |||||

| 3.15 | |||||

| 3.2 | |||||

| 3.25 | |||||

| 3.3 | |||||

| 3.35 | |||||

| 3.4 | |||||

| 3.45 | |||||

| 3.5 | |||||

| 3.3 | 6 | 20 | 62 | 118° | -0.005 |

| 3.4 | |||||

| 3.6 | |||||

| 3.7 | |||||

| 3.4 | 6 | 22 | 62 | 118° | -0.005 |

| 3.5 | |||||

| 3.51~3.99 | 4 | 20 | 50 | 118° | -0.005 |

| 3.8 | 6 | 24 | 66 | 118° | -0.005 |

| 3.9 |

BB Micro Drill - BB2055 (1PC)

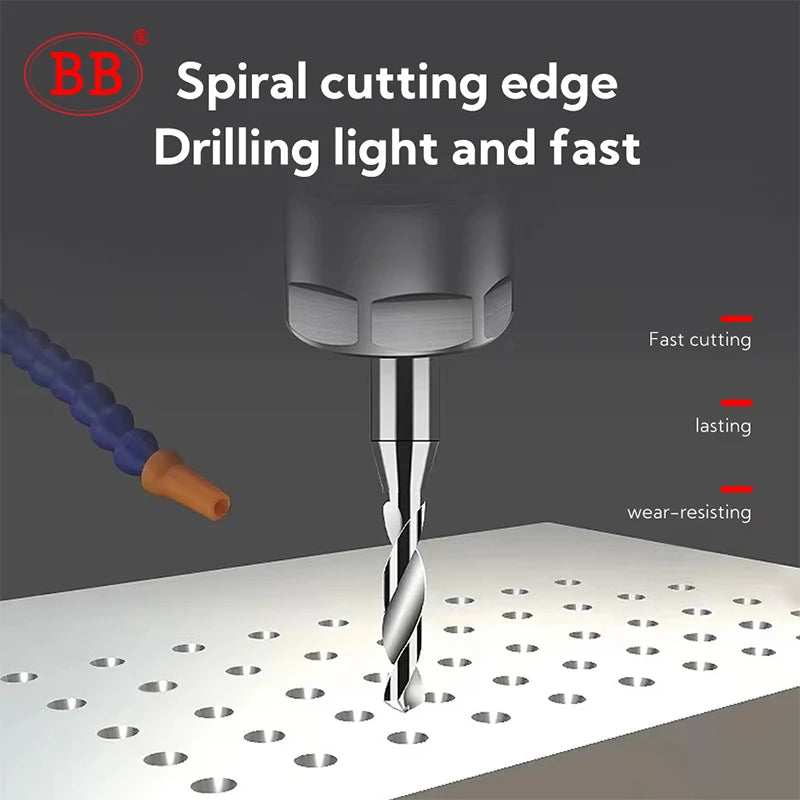

-Solid Carbide for Ultimate Precision & Durability.

Designed for machine use only—not for handheld drills.

BB 微型钻头 - BB2055 (1支)

核心特点

整体硬质合金材质,具备极高硬度与耐磨性,专为精密、持久加工而设计。

-Application:

Steel, Stainless Steel, Cast Iron, Tool & Die Steel, PCB (Circuit Board), Acrylic, etc.

适用材料:

钢材、不锈钢、铸铁、模具钢、电路板、亚克力等。

-Diameter of shank :4mm

Recommended Cutting Conditions

*Reference parameters are used as the general standard and need to be adjusted according to the Drilling environment.

*When abnormal noise occurs to the workpiece and equipment, please check the situation and change the parameters.

*When the highest speed does not reach the reference standard, please use the highest speed of your equipment for machining, but note that the feed speed also needs to be adjusted proportionally.

*Please fully provide cutting cooling water to the machining position and drilling edge.

*Table parameters are applicable to machining depth smaller than 3xDc. If the depth is greater than 3xDc, reduce the speed by 20%.

*According to the material and depth, select the grading machining method, please return to the top of the hole when grading feed. The grading amount is about 0.2 ~ 1Dc, when the diameter is less than 1mm, 0.1~0.2Dc.

*The beat of the drill bit should be less than 0.02mm.

HI, welcome to BB official store.

-We are professional manufacturer ,development and production of milling tools.

-We provide various tools for you . You can follow us and see more.

-You have free choice of collocation, pick different specifications and other tools in our store to you cart and pay them together. We will send the products you have picked as a package.

SHIPMENT

-We have already paid 80% of delivery cost .

-Orders processed timely after the payment verification.We ship products within 3 working days.

-The trade is cross-border, and Airmail is cheapest post which take a long time for delivery.If you need the item urgently ,please choose Express way.

-If you have not received your shipment within 60 days from payment, please contact us. We will track the shipment and get a reply to you as soon as possible.

We sincerely hope that BB tools will meet your full requirements. Please enjoy your online shopping.