BB Tool

BB 1/8 3/16 1/4 5/16 3/8 1/2 5/8 Imperial Inch End Mill Carbide CNC Milling Cutter Tool 2 3 4 Flute 3.175 12.7 Metal Steel

BB 1/8 3/16 1/4 5/16 3/8 1/2 5/8 Imperial Inch End Mill Carbide CNC Milling Cutter Tool 2 3 4 Flute 3.175 12.7 Metal Steel

受取状況を読み込めませんでした

Share

BB End Mill

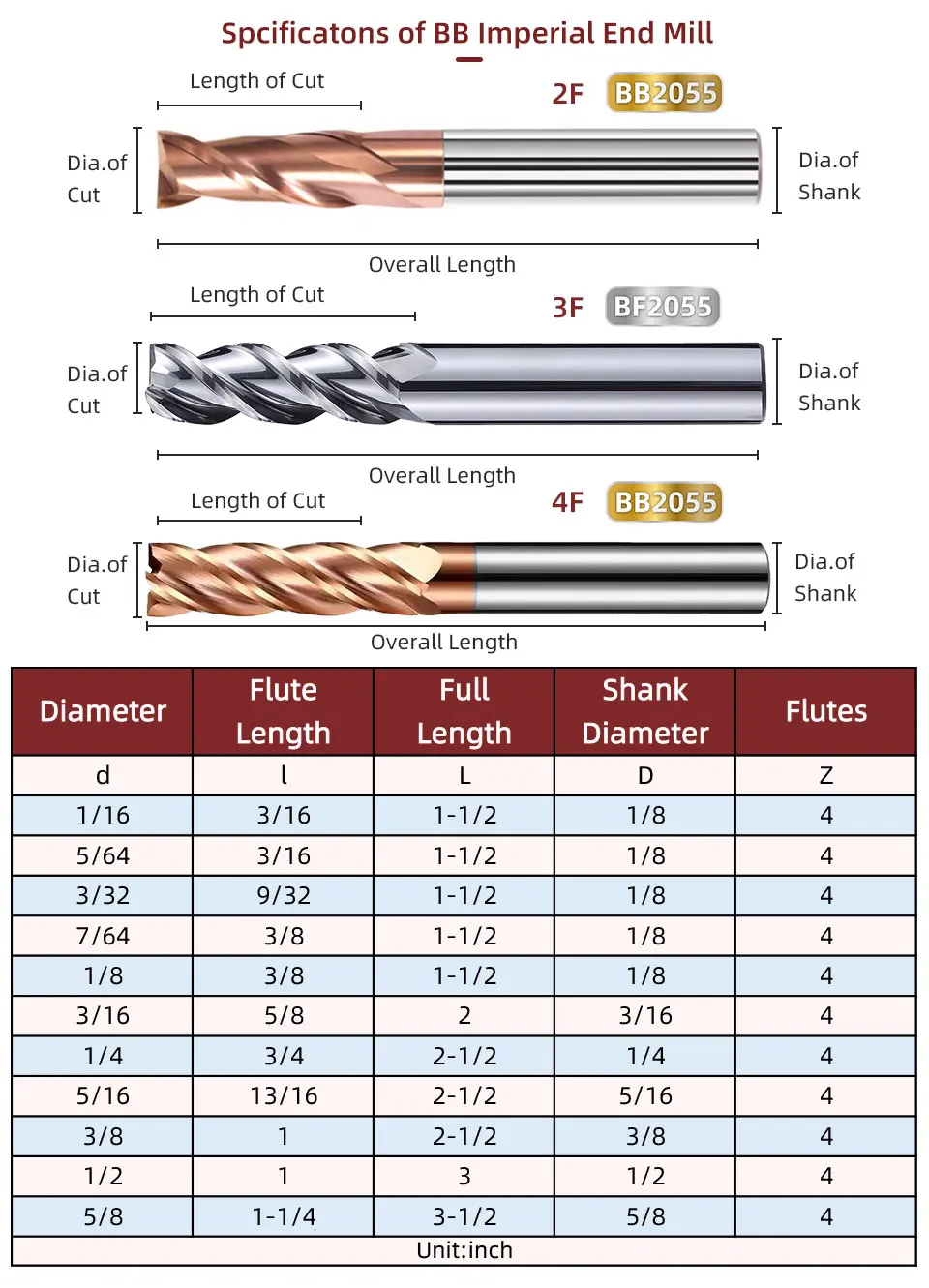

Dimensions(①Inch , ②mm)

①1/16xD1/8x3/16x1-1/2

①1/8xD1/8x1/2x1-1/2

②1/8xD4x11x50

①5/32xD5/32x9/16x2

①3/16xD3/16x5/8x2

②3/16*D6*15*50

①1/4xD1/4x3/4x2-1/2

②1/4*D8*20*60

①5/16xD5/16x13/16x2-1/2

②5/16xD8x20x60

①3/8xD3/8x7/8x2-1/2

②3l8xD10x30x75

①1/2xD1/2x1x3

②1/2*D14*45*100

②5/8xD16x45x100

Ultrafine Carbide Base Material

Good toughness and high hardness. Hard Carbide material alloy features high compatibility, high hardness, and high strength, ensuring smooth and fast cutting, making it a specialized milling cutter material for high-speed cutting applications

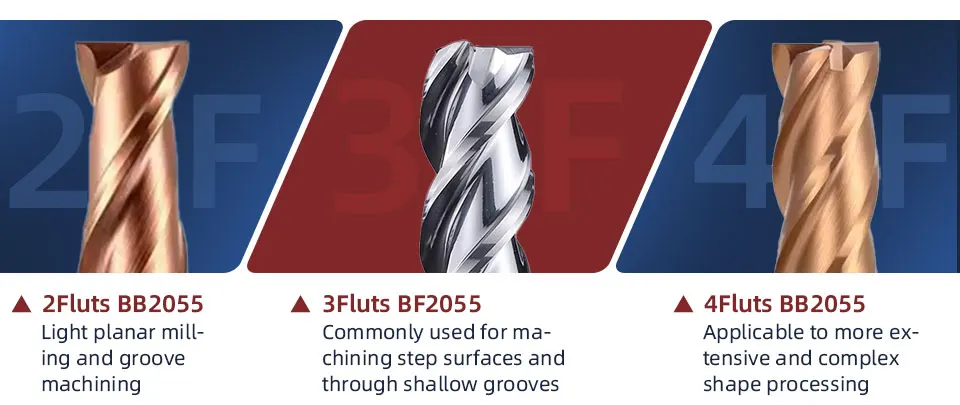

Multiple Blade Sharpness Options Available

2-flute end mills are typically used for simpler milling tasks such as light planar milling and groove machining. Due to their fewer cutting edges, they are suitable for small-scale roughing and the machining of less complex workpieces.

3-flute end mills find applications in a variety of milling tasks, especially where higher cutting efficiency and better surface quality are required. Three-flute end mills are commonly used for machining step surfaces and through shallow grooves, with their design aiding in enhancing cutting efficiency and improving cutting conditions.

4-flute end mills, with their four cutting edges, can provide higher cutting efficiency and stability, making them suitable for a wider range of milling tasks. They can be used not only for planar milling but also for groove machining, step surface machining, and contour milling of complex shapes. Additionally, 4-flute end mills can be used for keyway machining; although they are not specialized keyway mills, they can suffice in simpler scenarios.

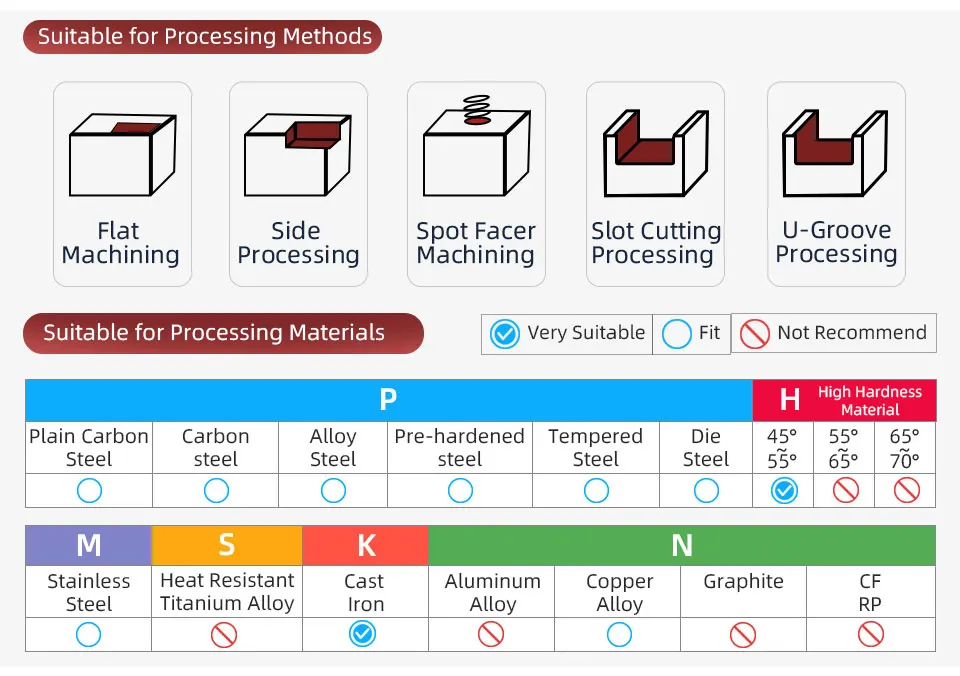

Suitable for Processing Methods

Flat Machining/Side Processing/Spot Facer Machining/Slot Cutting Processing/U-Groove

Processing etc.

Suitable for Processing Materials

Very Suitable/Fit/Not Recommend

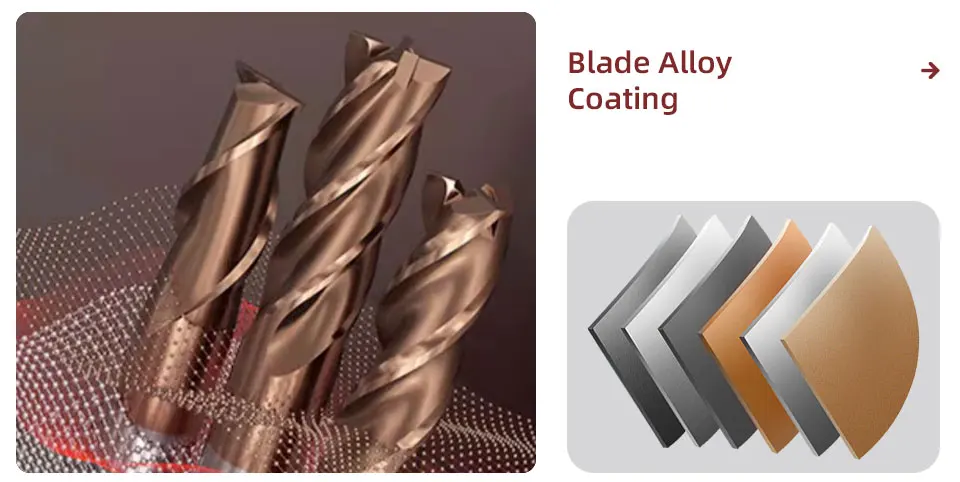

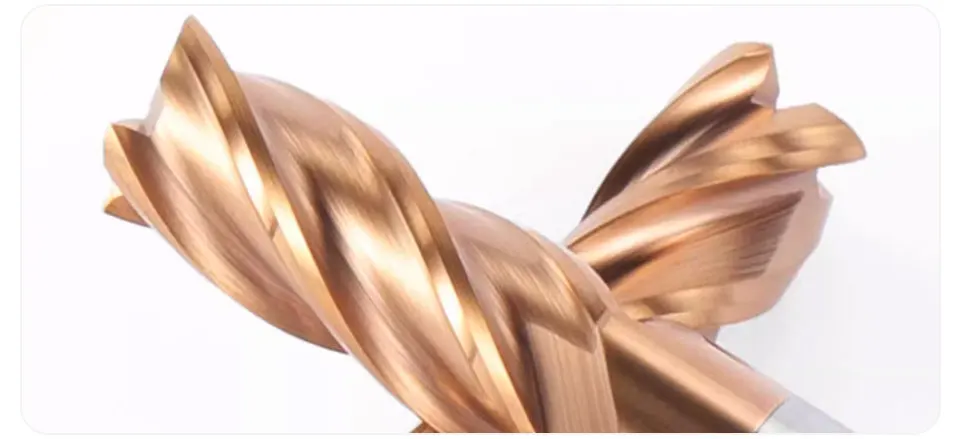

Blade Alloy Coating

The blade is coated with ALTIN (nano-gray coating), which enables direct machining of 58-degree heat-treated materials from roughing to finishing. This reduces the frequency of tool changes, enhances machine utilization rates, and saves on production time.

Steel Use:AlTiSiN Coating,Iron Plate , Stainless Steel ,Die Steel, Quenched Steel,etc.

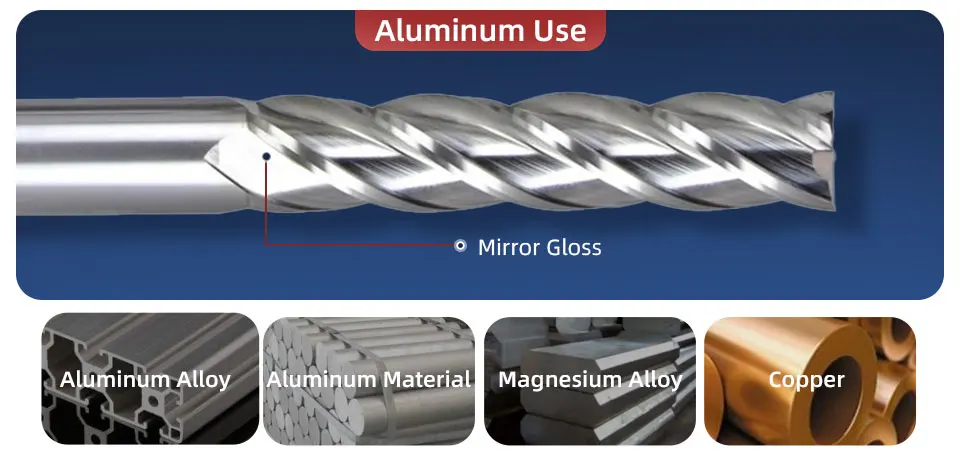

Aluminum Use:Mirror Gloss,Aluminum Alloy,Aluminum Material,Magnesium Alloy,Copper,etc.

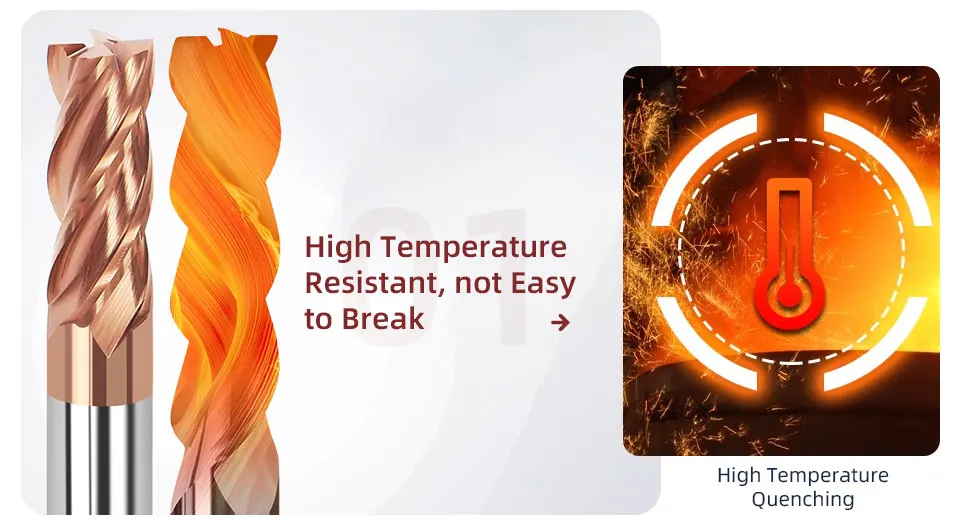

High Temperature Resistant, not Easy to Break

High Temperature Quenching

Reduce tool changes, improve rotation rate and significantly increase production efficiency.

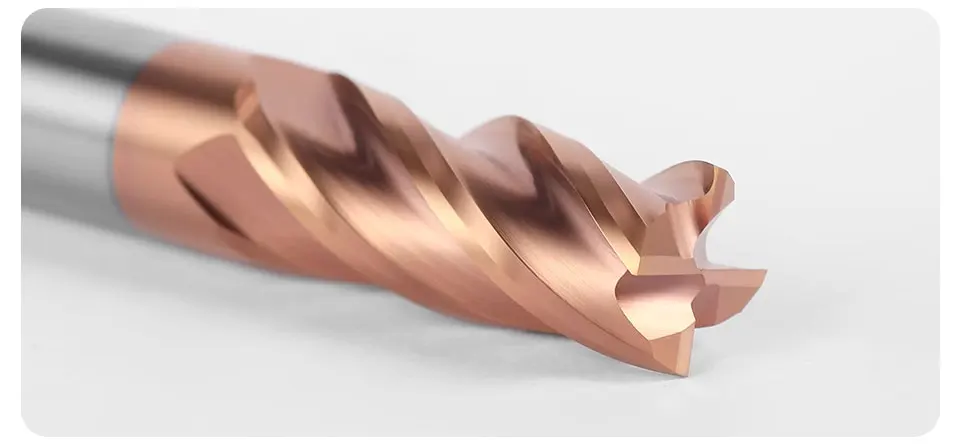

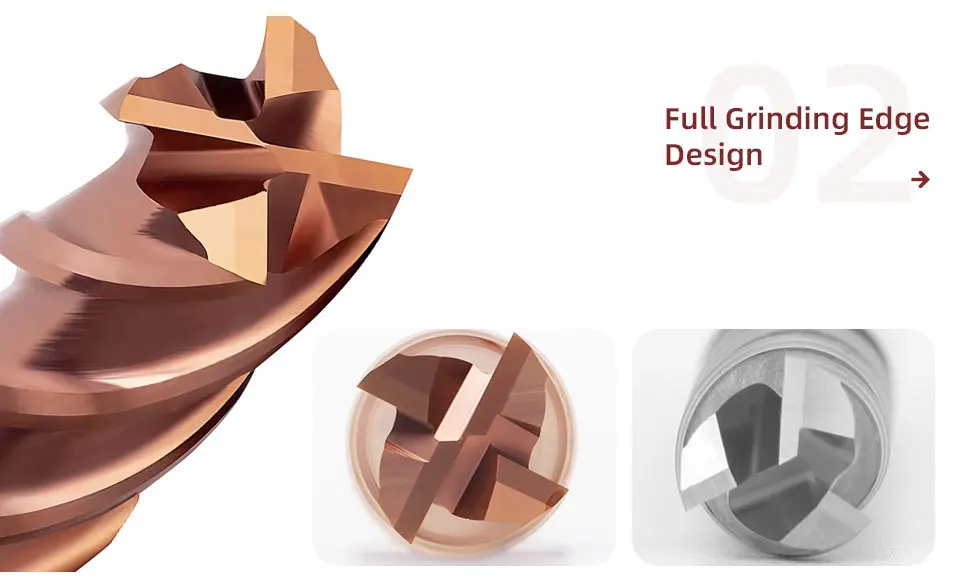

Full Grinding Edge Design

Under the condition of ensuring the chip space, a large core diameter design is adopted, which greatly enhances the rigidity and shock resistance of the tool, reducing the risk of tool breakage.

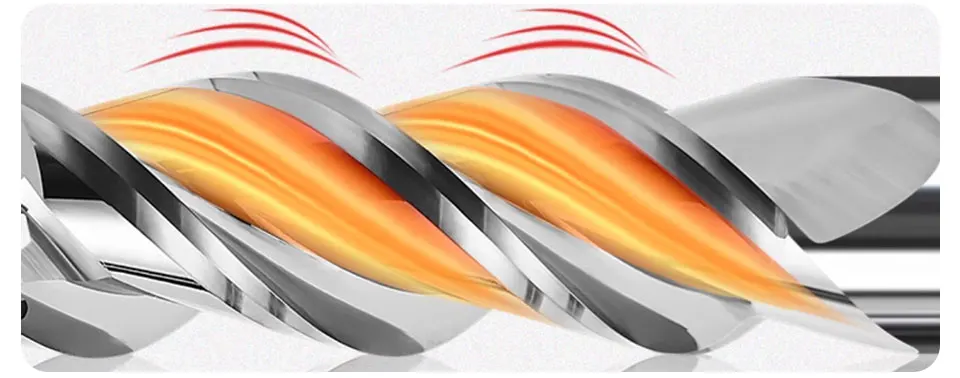

Large chip Groove Helical Angle Design

The cutting tool features a helical angle design, along with a widened cutting edge land and a large chip groove. This design enables the tool to smoothly evacuate chips during the cutting process, facilitating high-speed machining while effectively preventing chipping of the tool’s cutting edge.

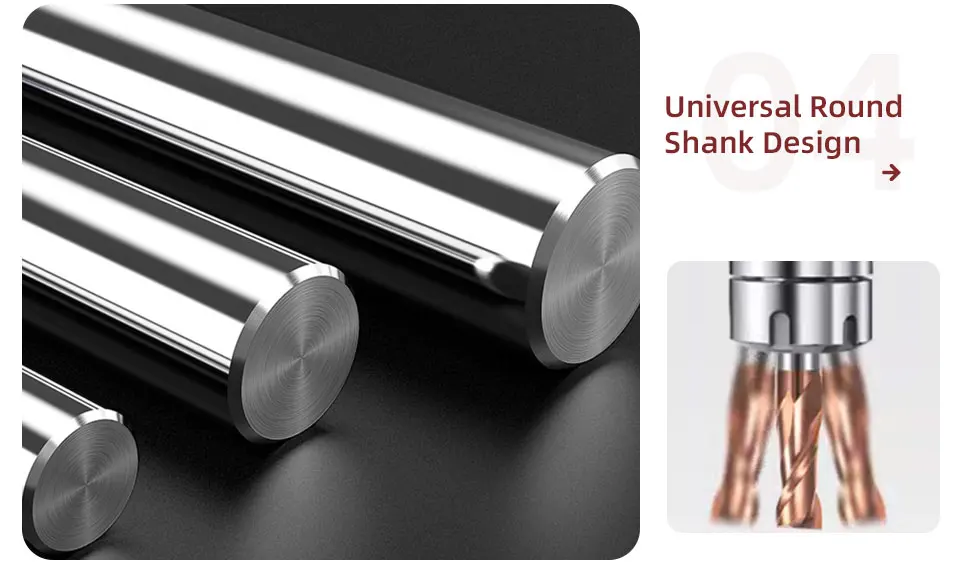

Universal Round Shank Design

The handle has a chamfered design, making it easier to clamp

Suggestions

01.Before using the tool, please measure the tool deviation. If the tool deviation accuracy exceeds 0.01mm, please correct it before cutting

02.The shorter the length of the tool extending out of the chuck, the better. If the tool extends out longer, it is necessary to reduce the speed, feed rate, or cutting amount

03.If abnormal vibration or sound occurs during re cutting, please reduce the speed and cutting amount until the situation improves

04.Steel cooling, preferably of spray type and puff type, can improve the use effect of milling cutter

05.Note: Not suitable for low-speed machines such as bench drills, electric drills, etc

HI, welcome to BB official store.

-We are professional manufacturer ,development and production of milling tools.

-We provide various tools for you . You can follow us and see more.

-You have free choice of collocation, pick different specifications and other tools in our store to you cart and pay them together. We will send the products you have picked as a package.

SHIPMENT

-We have already paid 80% of delivery cost .

-Orders processed timely after the payment verification.We ship products within 3 working days.

-The trade is cross-border, and Airmail is cheapest post which take a long time for delivery.If you need the item urgently ,please choose Express way.

-If you have not received your shipment within 60 days from payment, please contact us. We will track the shipment and get a reply to you as soon as possible.

We sincerely hope that BB tools will meet your full requirements. Please enjoy your online shopping.