BB Tool

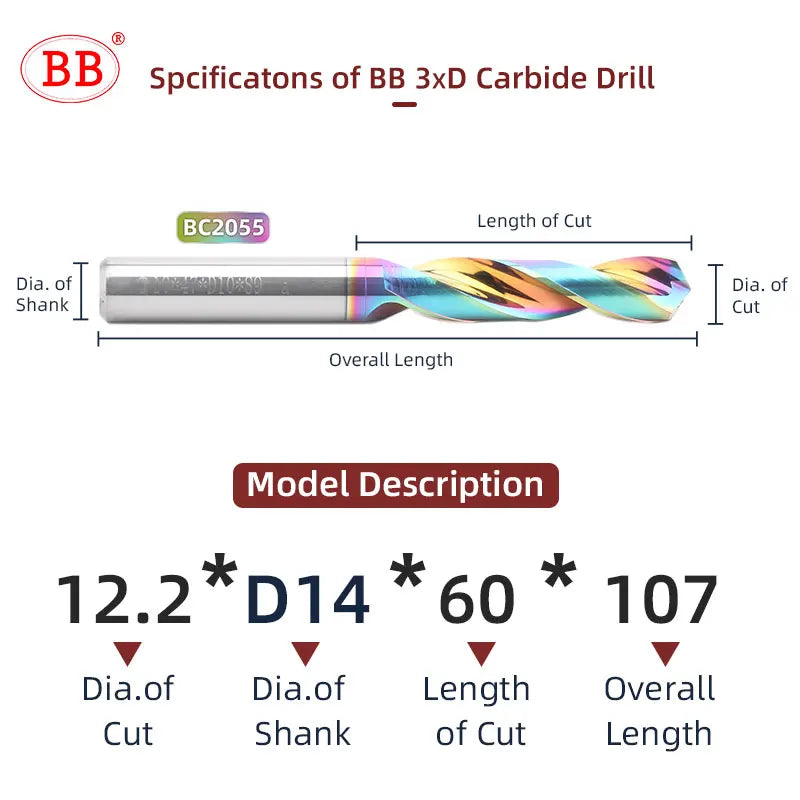

BB Internal Cooling Carbide Drill 3xD Diameter DLC CNC High Feed Machining for Aluminum Copper BC2055

BB Internal Cooling Carbide Drill 3xD Diameter DLC CNC High Feed Machining for Aluminum Copper BC2055

受取状況を読み込めませんでした

Share

| Name:BB Micro Drill Material:Micro-grained carbde | |||||

| Number of flutes:2 Series:BC2055 | |||||

| Diameter of shank:4mm~20mm Application:For general purpose | |||||

|

|||||

|

Cuting diameter |

Shank diameter (D) |

Cuttlng length (L) |

Total length (OL) |

Angle | Tolerance |

| 1.0~1.2 | 4 | 11 | 50 | 118° | -0.005 |

| 1.25~1.9 | 4 | 12 | 50 | 118° | -0.005 |

| 1.95~3.0 | 4 | 15 | 50 | 118° | -0.005 |

| 3.0~4.0 | 4 | 20 | 50 | 118° | -0.005 |

| 1.51~2.0 | 4 | 10 | 50 | 118° | -0.005 |

| 3.3~3.7 | 6 | 20 | 62 | 118° | -0.005 |

| 3.8~4.7 | 6 | 24 | 66 | 118° | -0.005 |

| 4.05~4.65 | 6 | 24 | 66 | 118° | -0.005 |

| 4.8~6.0 | 6 | 28 | 66 | 118° | -0.005 |

| 4.75~5.95 | 6 | 28 | 66 | 118° | -0.005 |

| 6.1~7.0 | 8 | 34 | 79 | 118° | -0.005 |

| 6.05~6.95 | 8 | 34 | 79 | 118° | -0.005 |

| 7.1~8.0 | 8 | 41 | 79 | 118° | -0.005 |

| 8.05~10.0 | 10 | 47 | 89 | 118° | -0.005 |

| 10.1~12.0 | 12 | 55 | 102 | 118° | -0.005 |

| 12.1~14.0 | 14 | 60 | 107 | 118° | -0.005 |

| 14.1~16.0 | 16 | 65 | 115 | 118° | -0.005 |

| 16.1~18.0 | 18 | 73 | 123 | 118° | -0.005 |

| 18.1~20.0 | 20 | 79 | 131 | 118° | -0.005 |

DLC (Diamond-Like Carbon) Coated End Mills

Experience the ultimate cutting edge. Our tools feature a DLC nano-coating that drastically reduces friction and wear, offering superior heat & oxidation resistance. This translates to faster cutting speeds, longer tool life, and a flawless finish on hardened steels, alloys, and composites.

DLC(类金刚石)涂层立铣刀

体验极致的切削性能。我们的刀具采用DLC纳米涂层,能显著降低摩擦与磨损,提供卓越的耐热和抗氧化性。这意味着更快的切削速度、更长的刀具寿命,以及在淬硬钢、合金及复合材料上获得完美的加工表面。

Conquer Tough Drilling Tasks with Ease

Crafted from premium solid carbide, this drill delivers exceptional wear resistance and strength, multiplying cutting efficiency to tackle your most demanding applications effortlessly.

轻松攻克严苛钻孔挑战

采用优质整体硬质合金制造,具备超凡的耐磨性与强度,成倍提升切削效率,让您游刃有余地应对最苛刻的加工任务。

Through-Tool Coolant Extends Tool Life by 30%

Under identical machining parameters, our internal cooling design increases tool life by 30% compared to external cooling. The double-helix coolant holes effectively reduce temperature, flush chips, enhance drilling stability, and accelerate overall efficiency.

内冷通孔设计,延长刀具寿命达30%

在相同加工参数下,我们的内冷设计相比外冷可延长刀具寿命30%。独特的双螺旋出水孔能有效降温、冲走切屑、增强钻孔稳定性,并全面提升加工效率。

Large Core Diameter for Strength & Chip Flow

This design features an enlarged core diameter that maintains sufficient chip capacity while significantly enhancing the tool's structural hardness and overall durability.

大芯径设计:兼顾强度与排屑

该设计采用加大的芯径,在保证充足容屑空间的同时,显著提升了刀具的结构硬度与整体耐用性。

High-Performance Fine-Grain Carbide Substrate

Crafted from an advanced fine-grained carbide material, this drill bit offers superior wear resistance and exceptional strength — engineered specifically for high-hardness materials and high-speed cutting applications.

高品质超细晶粒硬质合金基材

采用先进的超细晶粒硬质合金材料制成,具备出色的耐磨性与卓越的强度,专为高硬度材料的高速切削应用而设计。

Sharp, Wear-Resistant & Universally Compatible

A sharp cutting edge combined with exceptional wear resistance delivers clean, efficient drilling. The chamfered round shank ensures strong compatibility and secure clamping across a wide range of tool holders and machines.

锋利、耐磨、通用兼容

锋利的切削刃结合卓越的耐磨性,实现洁净高效的钻孔效果。倒角圆柄设计确保广泛的兼容性与稳固夹持,适配多种刀柄和机床。

Machinable Material

Suitable for copper, aluminum, zinc alloy and other viscous materials

Shopkeeper Tips

01:The drill bit requires high-speed rotation, the specific parameters can be obtained from the reference tachometer

02:Due to the particularity of brittleness and hardness of this product, problems such as cracking and fracture during use are not covered (electric hand drill is prohibited)

03:recommend CNC numerical control equipment use (high durability) second bench drill use (improper operation, scrap rate is relatively high)