BB Tool

BB Micro Drill Solid Carbide Bit Mini CNC Aluminum Hole Making External Cooling 3xD Shank Diameter 4mm D4 BF2055 0.3~3.99mm

BB Micro Drill Solid Carbide Bit Mini CNC Aluminum Hole Making External Cooling 3xD Shank Diameter 4mm D4 BF2055 0.3~3.99mm

受取状況を読み込めませんでした

Share

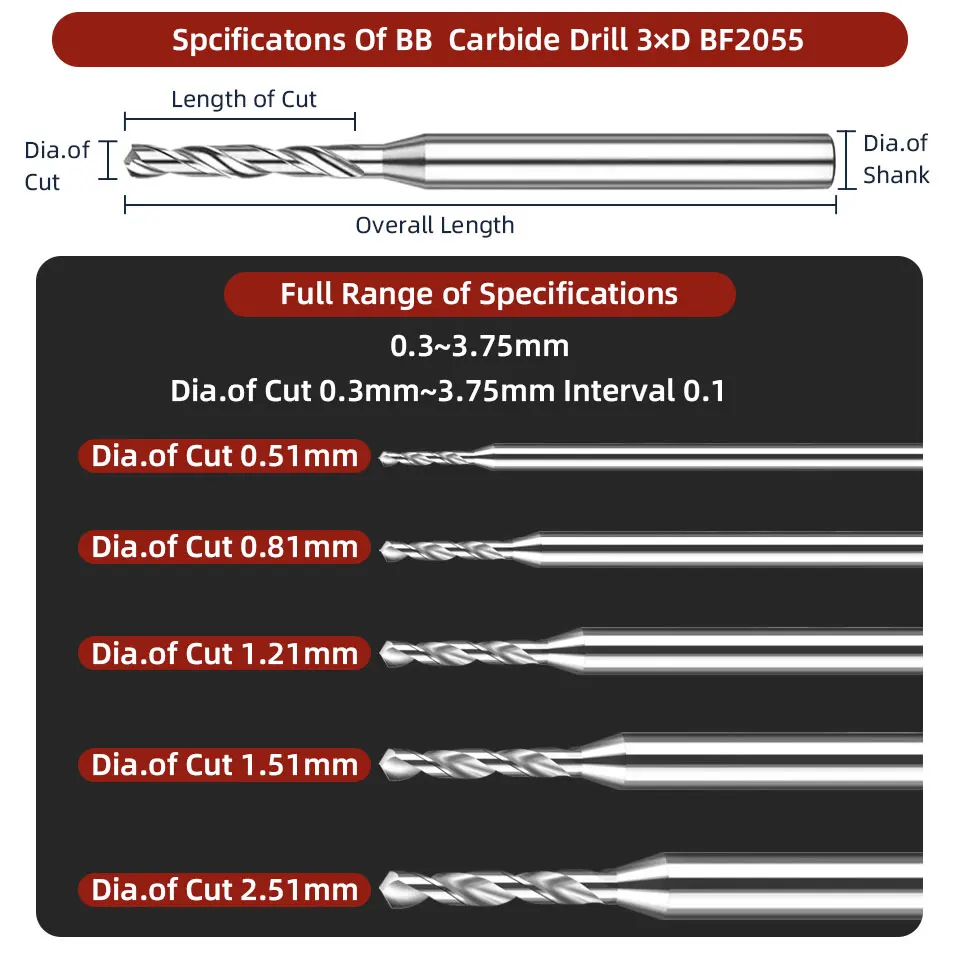

| Name:BB Micro Drill Material:Micro-grained carbde | |||||

| Number of flutes:2 Series:BF2055 | |||||

| Diameter of shank:4mm Application:For general purpose | |||||

|

|||||

|

Cuting diameter |

Shank diameter (D) |

Cuttlng length (L) |

Total length (OL) |

Angle | Tolerance |

| 0.3~0.4 | 4 | 4 | 50 | 118° | -0.005 |

| 0.41~0.5 | 4 | 5 | 50 | 118° | -0.005 |

| 0.51~0.99 | 4 | 6 | 50 | 118° | -0.005 |

| 1.0~1.5 | 4 | 8 | 50 | 118° | -0.005 |

| 1.51~2.0 | 4 | 10 | 50 | 118° | -0.005 |

| 1.5 | 4 | 12 | 50 | 118° | -0.005 |

| 2.01~2.5 | 4 | 12 | 50 | 118° | -0.005 |

| 2.51 | 4 | 12 | 50 | 118° | -0.005 |

| 2.5~3.0 | 4 | 15 | 50 | 118° | -0.005 |

| 3.01~3.5 | 4 | 18 | 50 | 118° | -0.005 |

| 3.51~3.99 | 4 | 20 | 50 | 118° | -0.005 |

BB Mirco Drill-BB2055(1PCS)

· Solid Carbide Construction: The entire drill bit is crafted from solid carbide, delivering exceptional wear resistance and durability for extended tool life in precision applications.

· Important Handling Notice: Due to the inherent rigidity of solid carbide, the bit is less tolerant to lateral stress and vibration. It is strictly prohibited to use with hand-held electric drills or in any unstable machining setup to prevent breakage.

BB 微型钻头 - BB2055 (1支)

· 整体硬质合金结构: 钻头整体采用硬质合金制成,具有卓越的耐磨性和耐用性,在精密加工中能显著延长工具寿命。

· 重要操作须知: 由于硬质合金材料本身的高刚性,本钻头对侧向应力和振动的耐受度较低。严禁在手电钻或任何不稳定的加工环境下使用,以防断裂。

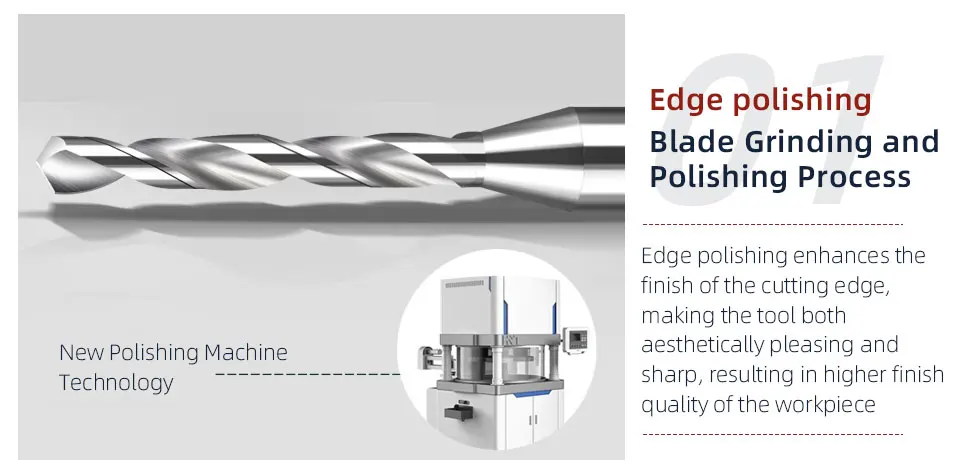

Precision Edge Grinding & Polishing Process

The edge polishing process enhances both the sharpness and surface finish of the cutting edge. This results in a superior workpiece surface quality while also giving the tool an aesthetically refined appearance.

刃口研磨抛光工艺

刃口抛光工艺不仅提升了切削刃的锋利度,也改善了其表面光洁度。这一工序确保了卓越的工件表面质量,同时赋予了刀具精致的外观。

Premium Ultra-Fine Grain Carbide

Engineered with a brand-new, ultra-fine grain carbide substrate, it achieves unrivaled material hardness and exceptional wear resistance for the most demanding applications.

高品质超细晶粒硬质合金

采用全新的超细晶粒硬质合金基体打造,实现了无与伦比的材料硬度与卓越的耐磨性,足以应对最严苛的加工挑战。

Large Core DiameterDesign

Significantly enhances the stability and shock resistance of the cutting tool, thereby greatly reducing the risk of tool breakage.

大芯径设计

显著增强切削工具的稳定性与抗冲击性,从而大幅降低断刀风险。

Passivation & Precision Grinding: For a Burr-Free Edge & Longer Life

The passivation process enhances the tool's corrosion and wear resistance. Combined with precision grinding to achieve a completely burr-free cutting edge, this ensures smoother cutting and significantly extends tool lifespan.

钝化与精磨工艺:实现无毛刺刃口,延长使用寿命

钝化处理提升了刀具的耐腐蚀性与耐磨性。结合实现完全无毛刺刃口的精密研磨,确保了切削更顺畅,并显著延长了刀具寿命。

Spiral Flute Design for Effortless Chip Evacuation

The precision-polished spiral flutes ensure smooth, clog-free chip removal. This efficient evacuation directly minimizes burr formation during the cutting process.

螺旋槽设计,实现轻松排屑

经过精密抛光的螺旋槽确保切屑顺畅排出,无堵塞。这种高效的排屑方式能直接减少切削过程中毛刺的产生。

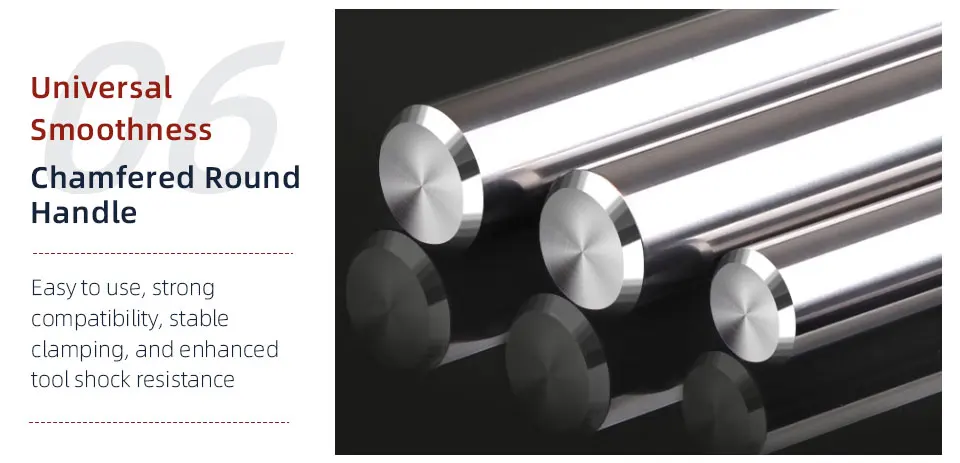

Versatile Chamfered Round Shank for Stable Operation

Designed for ease of use and broad compatibility, the chamfered round shank ensures stable clamping in a wide range of tool holders while also enhancing shock absorption during operation.

通用倒角圆柄,保障稳定操作

专为易用性与广泛兼容性设计,倒角圆柄可在多种刀柄中实现稳定夹持,同时增强加工时的减震能力。

Suitable for Precision Finishing Operations

Ideal for sharp machining applications, this tool consistently delivers workpieces with a high-quality surface finish.

适用于精密精加工

是锋利切削应用的理想选择,能持续稳定地加工出具有高质量表面光洁度的工件。

Wide Range of Applicable Materials:

Aluminum Parts, Copper Parts, Etc.

Applicable Equipment:CNC Milling Machines, Machining Centers, CNC Engraving Machines

-Application:

Steel, stainless steel, cast iron, die steel, circuit board,acrylic and so on.

-Diameter of shank :4mm

Recommended Cutting Conditions

*Reference parameters are used as the general standard and need to be adjusted according to the Drilling environment.

*When abnormal noise occurs to the workpiece and equipment, please check the situation and change the parameters.

*When the highest speed does not reach the reference standard, please use the highest speed of your equipment for machining, but note that the feed speed also needs to be adjusted proportionally.

*Please fully provide cutting cooling water to the machining position and drilling edge.

*Table parameters are applicable to machining depth smaller than 3xDc. If the depth is greater than 3xDc, reduce the speed by 20%.

*According to the material and depth, select the grading machining method, please return to the top of the hole when grading feed. The grading amount is about 0.2 ~ 1Dc, when the diameter is less than 1mm, 0.1~0.2Dc.

*The beat of the drill bit should be less than 0.02mm.

HI, welcome to BB official store.

-We are professional manufacturer ,development and production of milling tools.

-We provide various tools for you . You can follow us and see more.

-You have free choice of collocation, pick different specifications and other tools in our store to you cart and pay them together. We will send the products you have picked as a package.

SHIPMENT

-We have already paid 80% of delivery cost .

-Orders processed timely after the payment verification.We ship products within 3 working days.

-The trade is cross-border, and Airmail is cheapest post which take a long time for delivery.If you need the item urgently ,please choose Express way.

-If you have not received your shipment within 60 days from payment, please contact us. We will track the shipment and get a reply to you as soon as possible.

We sincerely hope that BB tools will meet your full requirements. Please enjoy your online shopping.