BB Tool

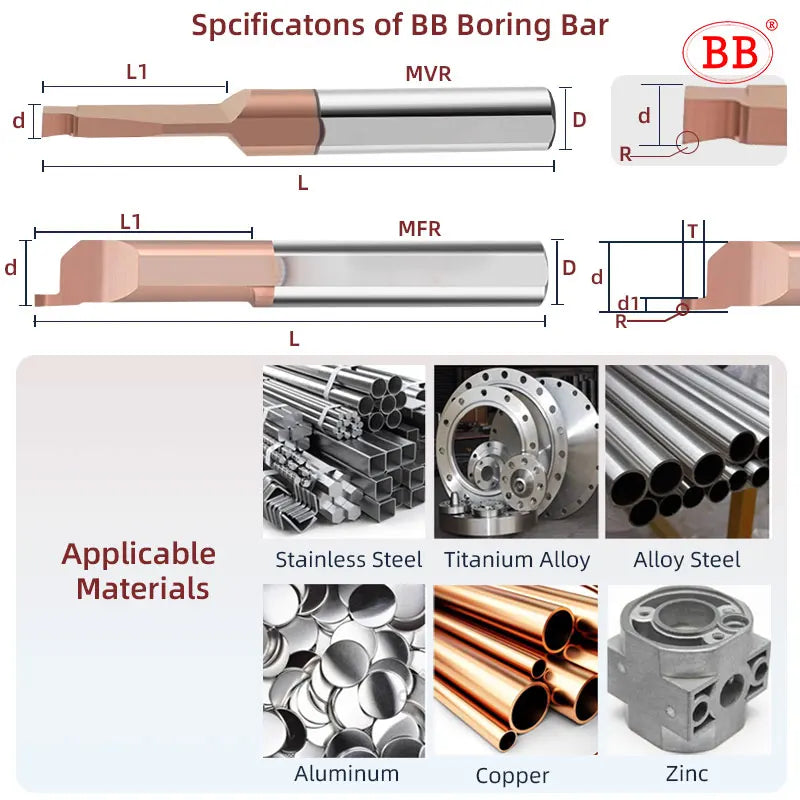

BB Small Bore Cutter Mini Turning Grooving Tool NC CNC Lath MVR MFR MFL Solid Carbide

BB Small Bore Cutter Mini Turning Grooving Tool NC CNC Lath MVR MFR MFL Solid Carbide

Не удалось загрузить сведения о доступности самовывоза

Делиться

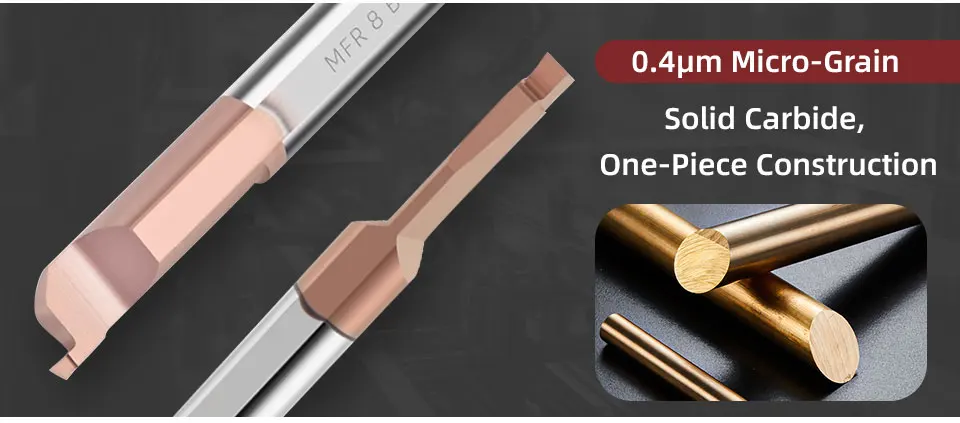

0.4μm Micro-Grain Solid Carbide, One-Piece Construction

Vibration-resistant and durable solid carbide, prevents tool breakage

TisiN Nano-Coating

High Heat Resistance/High Wear Resistance

Multi-layer coating, improved wear resistance, and longer service life

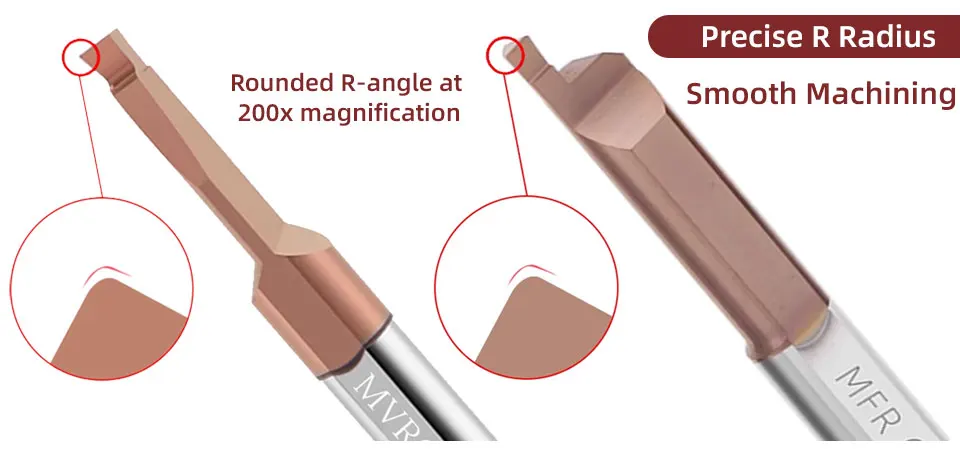

Precise R Radius Smooth Machining

Rounded R-angle at 200x magnification

Precision-ground radius for high-accuracy arc edge, preventing chipping and ensuring smoother machining

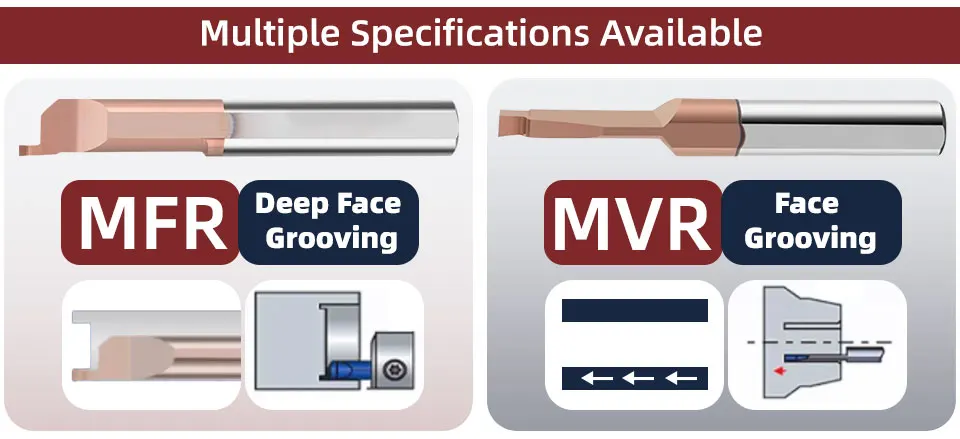

Multiple Specifications Available

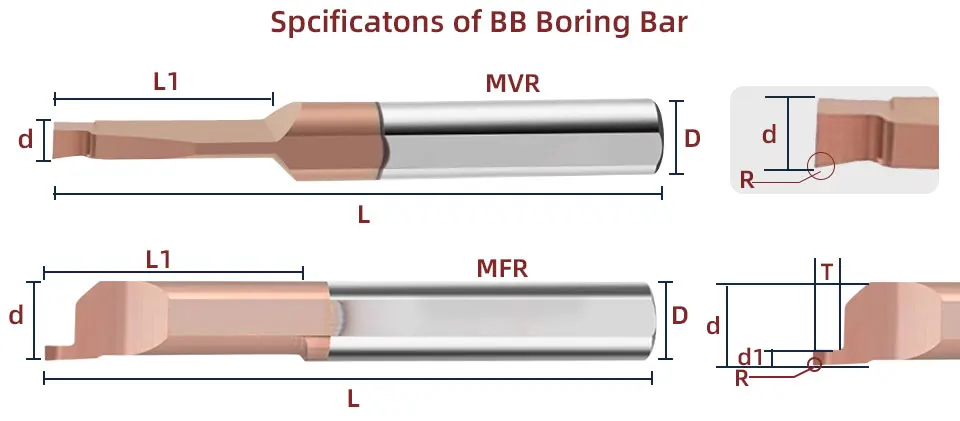

MFR:Deep Face Grooving

MVR:Face Grooving

Boring Bar for Internal Grooving

MFR

High Efficiency, Reliability, and Speed

Specialized for Small-Diameter Grooving

Sharp, Efficient, and Wear-Resistant Boring Bar for Small Hole Grooving

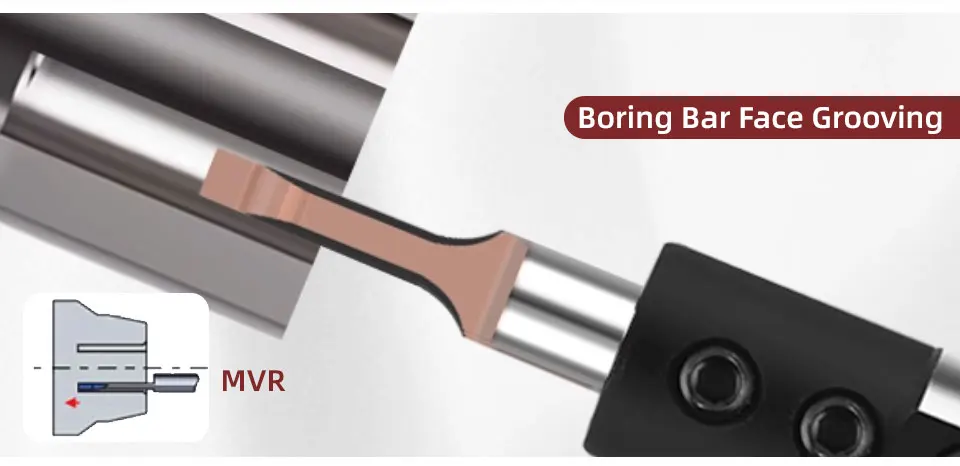

Boring Bar Face Grooving

MVR

Specialized Boring Tool for High Hardness and High Precision

Applicable Materials: Stainless steel, mold steel, alloy steel, cast iron, etc., with a hardness below 45 HRC.

Turning Test Under the Same Conditions

Our MVR MFR Boring Tool:

No Significant Wear on Cutting Edge

High Hardness, Minimal Wear

Company A’s Product:

Obvious Wear on Cutting Edge

oor Wear Resistance, Significant Wear

Angled Design

Unique angled cutting edge design reduces cutting resistance, ensures smooth machining, and minimizes tool changes

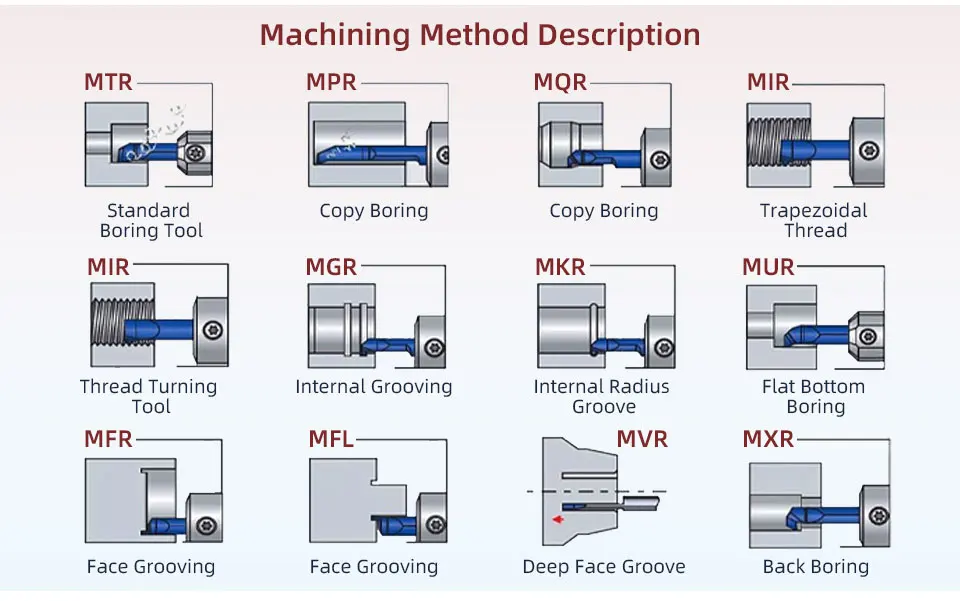

Machining Method Description

MPR, Standard Boring Tool

MQR, Copy Boring

MIR, Copy Boring

MIR, Trapezoidal Thread

MIR, Thread Turning Tool

MGR, Internal Grooving

MKR, Internal Radius Groove

MUR, Flat Bottom Boring

MFR, Face Grooving

MFL, Face Grooving

MVR, Deep Face Groove

MXR, Back Boring

Model Interpretation MFR6B2.0L22

Model/Represents

M= Micro Boring Tool

R: R= Right-hand Thread /L= Left-hand Thread

F:T= Turning / P= Profiling & Boring

Q= Profiling & Boring

I= Threading

D= Thread Relief, Grooving, Chamfering

C= Chamfering & Boring

G= Grooving

K= Radius Grooving

F= Axial Grooving

Z= Axial Radius Grooving

X= Reverse Turning / Internal Turning

U= Profiling

W= Chamfering & Profiling

V= Deep Axial Grooving

M= Multi-functional Micro Boring Tool

N= Turning

6 Shank Diameter:

3=3.0mm

4=4.0mm

5=5.0mm

6=6.0mm

8=8.0mm

10=10.0mm

B2.0 Boring:

R0.2= Nose Radius R0.2mm

Threading(Variable Pitch) A60 A55 TR

(Fixed Pitch) ISO UN NPT ACME

Grooving (Groove Width):

B1.0=1.0mm

B1.5=1.5mm

B2.0=2.0mm

L22 Length :

L5=5mm

L10=10mm

L15=15mm

L22=22mm

L35=35mm