BB Tool

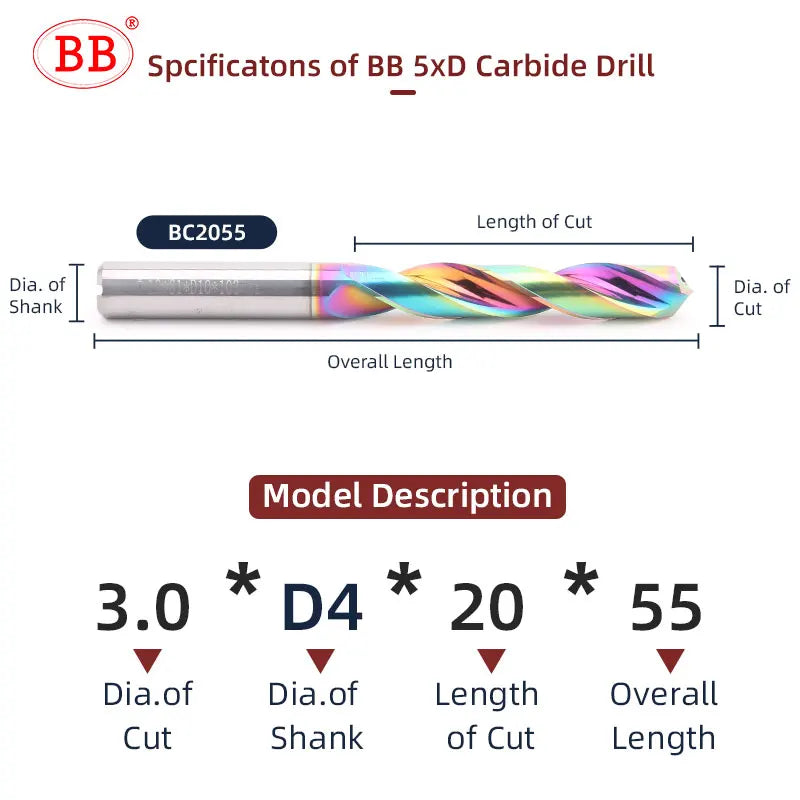

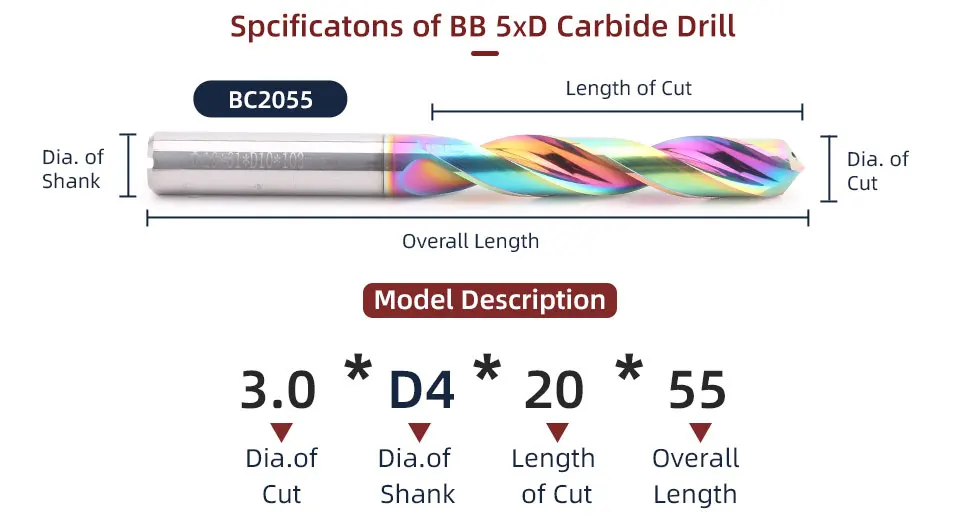

BB Solid Carbide Internal Cooling Drill DLC PRO Bit Hole Drilling 5xD Cutting CNC Tool for Aluminum Diameter 3.0-20mm

BB Solid Carbide Internal Cooling Drill DLC PRO Bit Hole Drilling 5xD Cutting CNC Tool for Aluminum Diameter 3.0-20mm

Не удалось загрузить сведения о доступности самовывоза

Делиться

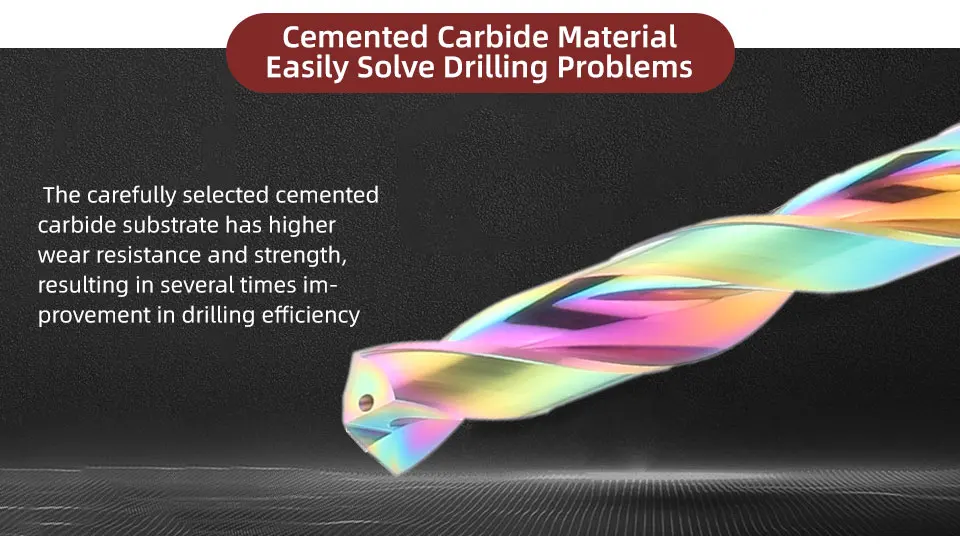

Cemented Carbide Material Easily Solve Drilling Problems

The carefully selected cemented carbide substrate has higher wear resistance and strength, resulting in several times improvement in drilling efficiency

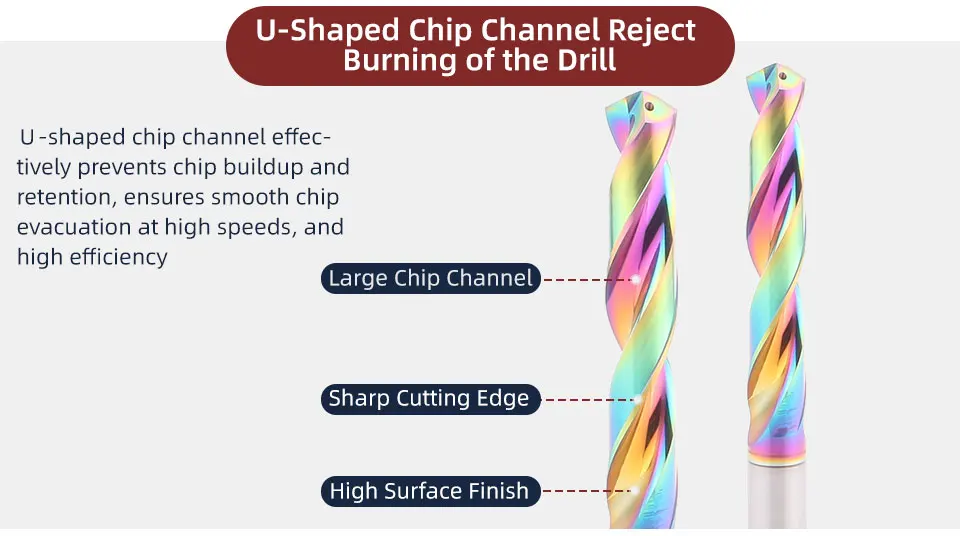

U-Shaped Chip Channel Reject Burning of the Drill

∪-shaped chip channel effectively prevents chip buildup and retention, ensures smooth chip evacuation at high speeds, and high efficiency

Large Chip Channel,Sharp Cutting Edge,High Surface Finish

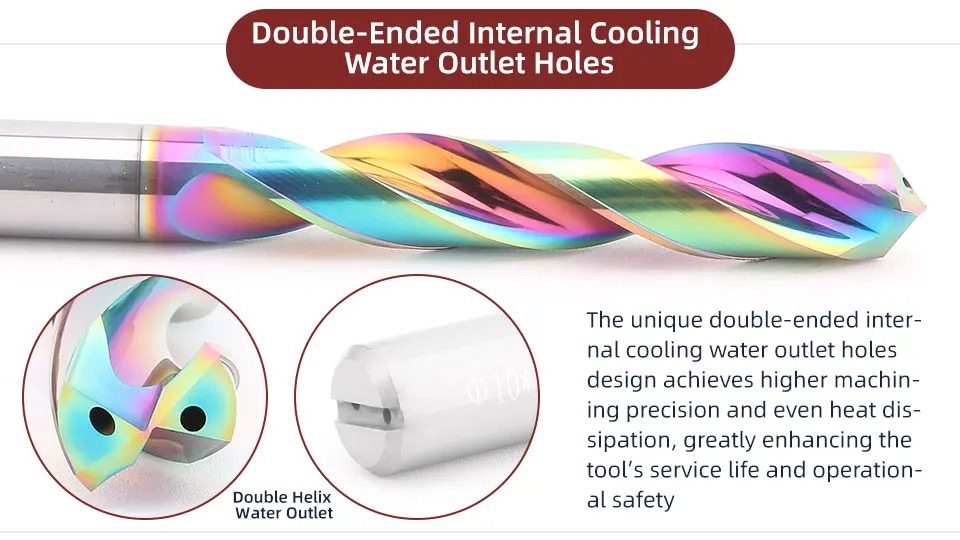

Double-Ended Internal Cooling Water Outlet Holes

The unique double-ended internal cooling water outlet holes design achieves higher machining precision and even heat dissipation, greatly enhancing the tool’s service life and operational safety

Double Helix Water Outlet

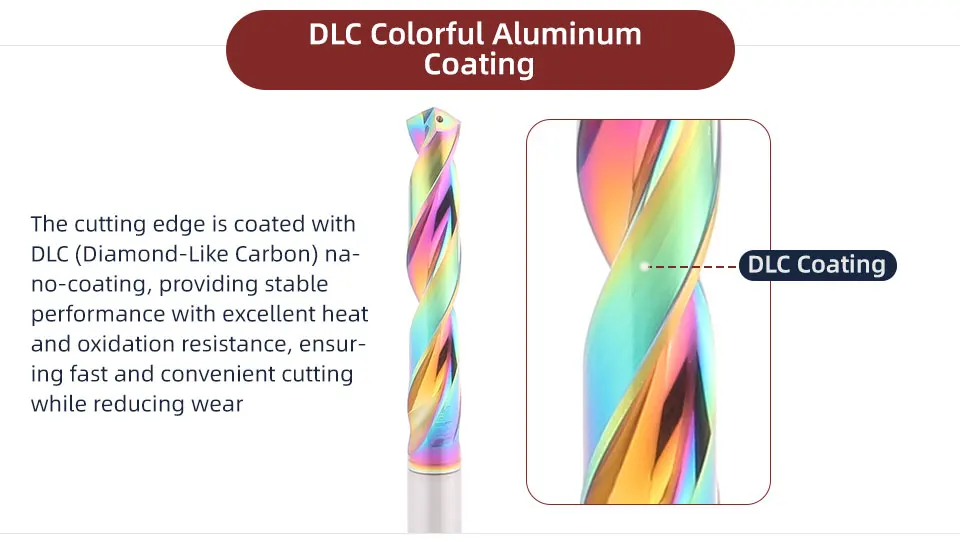

DLC Colorful Aluminum Coating

The cutting edge is coated with DLC (Diamond-Like Carbon) nano-coating, providing stable performance with excellent heat and oxidation resistance, ensuring fast and convenient cutting while reducing wear

Fully Ground Cutting Edge Sharp Drilling

Wear-resistant and durable, providing a strong guarantee for the service life of the drill bit

Universal Chamfered Round Shank Strong Compatibility

Easy to use, with good compatibility, does not slip during use

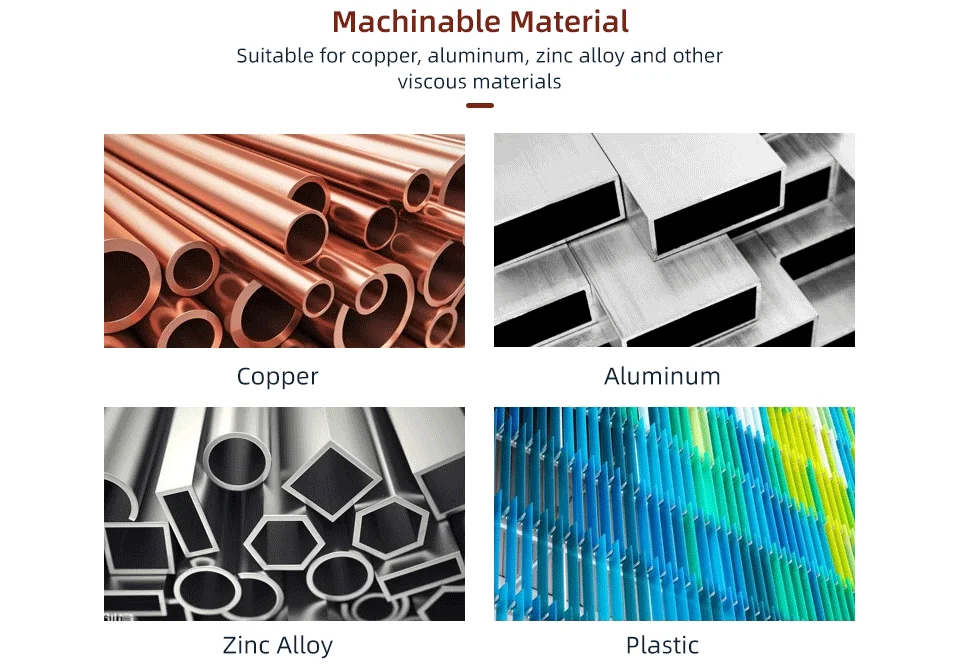

Machinable Material

Suitable for copper, aluminum, zinc alloy and other viscous materials

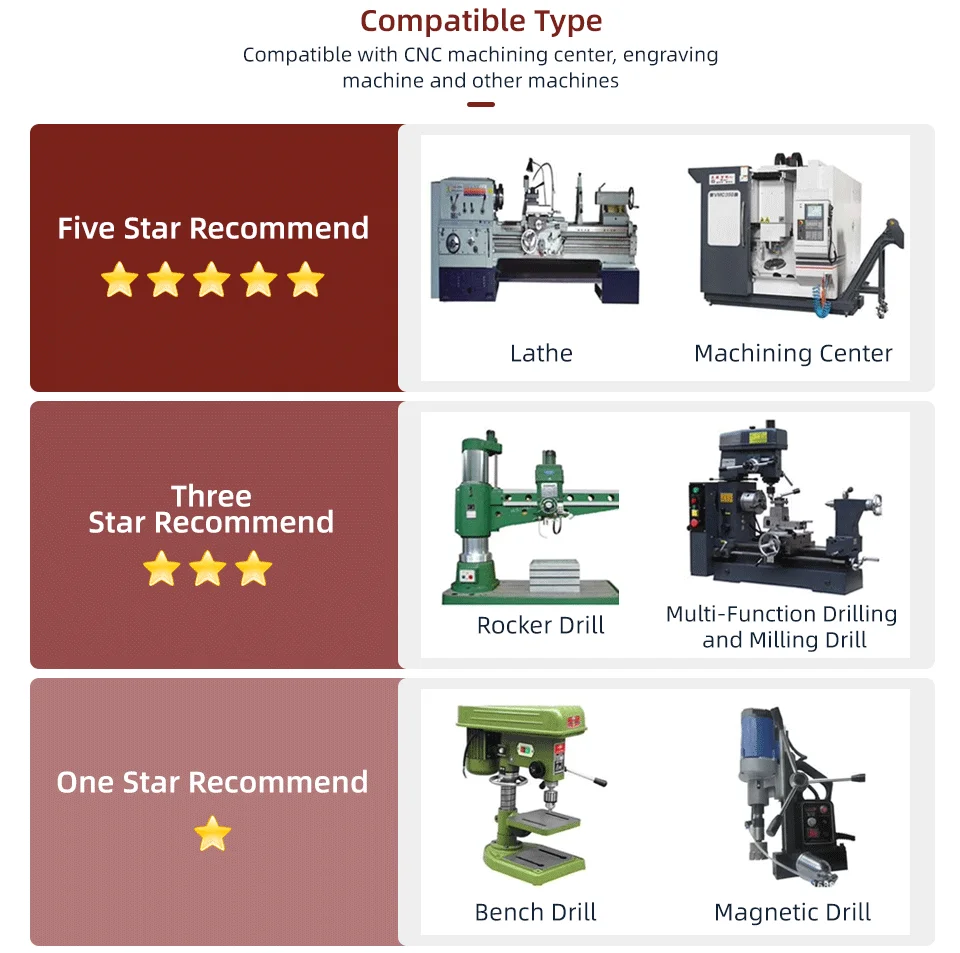

Compatible Type

Compatible with CNC machining center, engraving machine and other machines

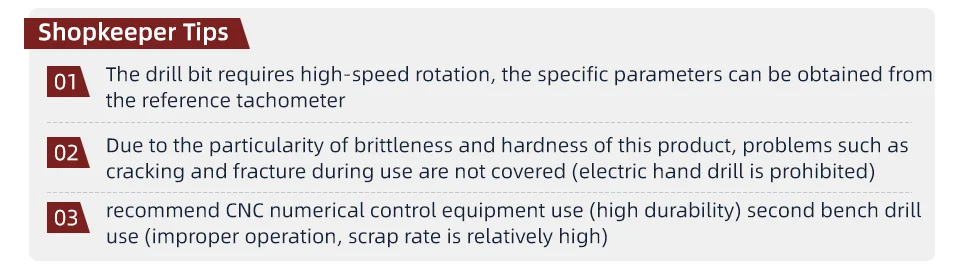

Shopkeeper Tips

01:The drill bit requires high-speed rotation, the specific parameters can be obtained from the reference tachometer

02:Due to the particularity of brittleness and hardness of this product, problems such as cracking and fracture during use are not covered (electric hand drill is prohibited)

03:recommend CNC numerical control equipment use (high durability) second bench drill use (improper operation, scrap rate is relatively high)