BB Tool

BB Thermal Friction Hot Melt Short Drill Bit Solid Carbide Hole Making Tool M3 M4 M5 M6 M8 M10

BB Thermal Friction Hot Melt Short Drill Bit Solid Carbide Hole Making Tool M3 M4 M5 M6 M8 M10

Не удалось загрузить сведения о доступности самовывоза

Делиться

BB Thermal Friction Drill

Application

-Applicable workpiece aperture: diameter 1.8-32mm

-Applicable workpiece thickness: 0.8-12mm;

-Applicable workpiece materials: iron, alloy, stainless steel, brass, copper, aluminum alloy and other metals;

-Applicable products: metal furniture, metal doors and windows, metal shelves, hardware building materials, auto parts, fitness equipment, medical equipment, heat exchange system, air conditioning pipeline, pressure vessel, water separator, lighting, etc.

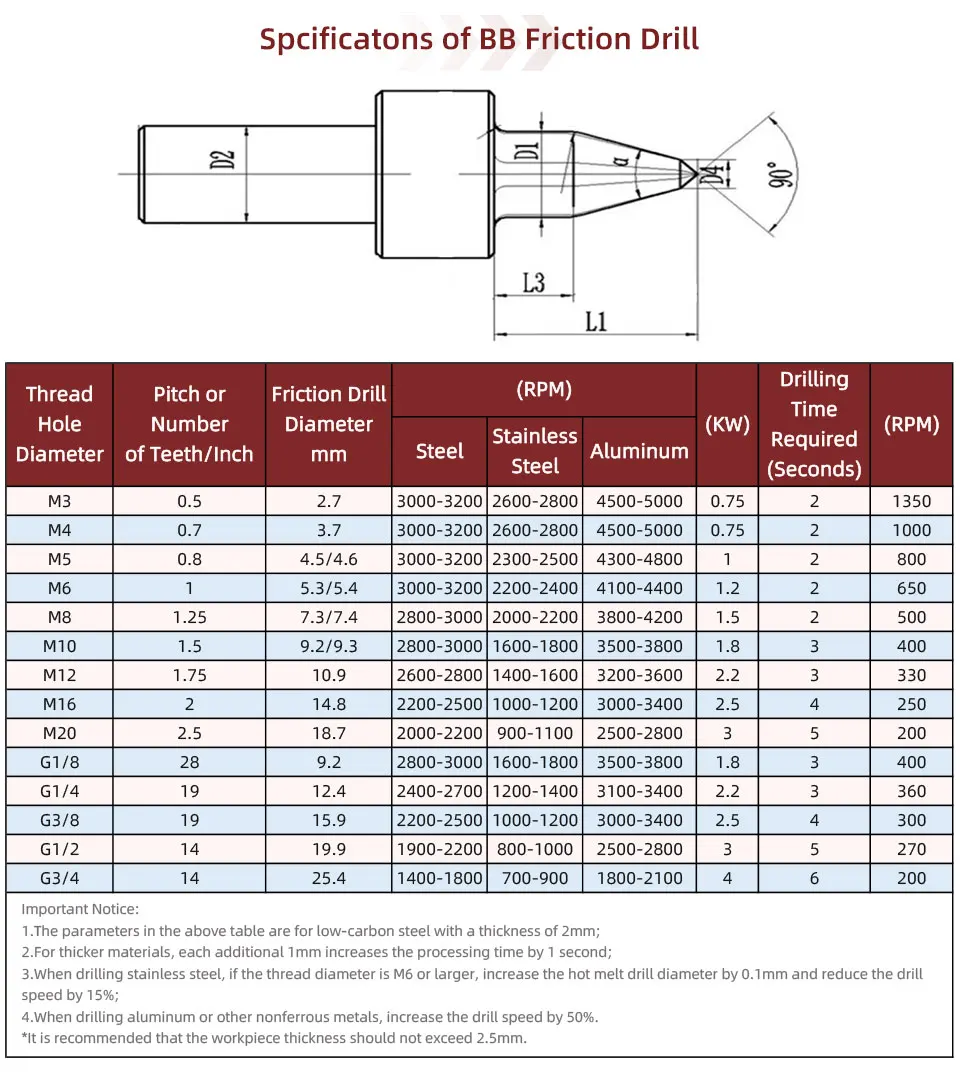

The parameters in the above table are for low-carbon steel with a thickness of 2mm;

For thicker materials, each additional 1mm increases the processing time by 1 second;

When drilling stainless steel, if the thread diameter is M6 or larger, increase the hot melt drill diameter by 0.1mm and reduce the drill speed by 15%;

When drilling aluminum or other nonferrous metals, increase the drill speed by 50%.

*It is recommended that the workpiece thickness should not exceed 2.5mm.

3l8=3/8,inch

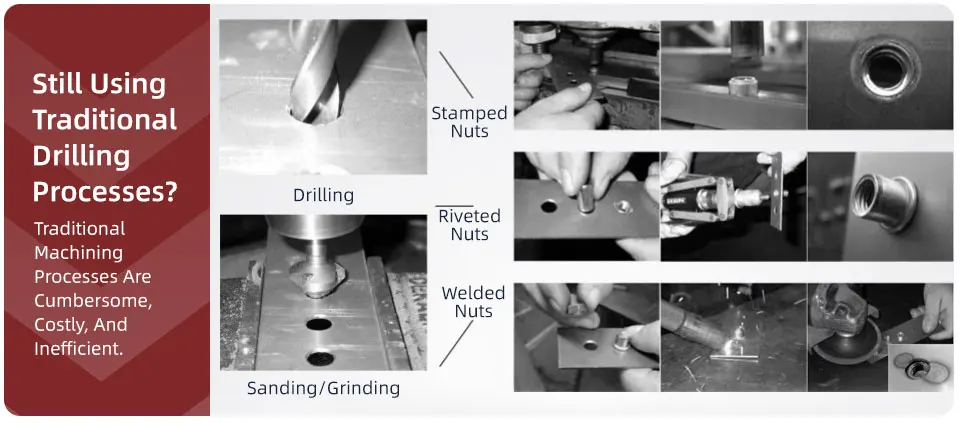

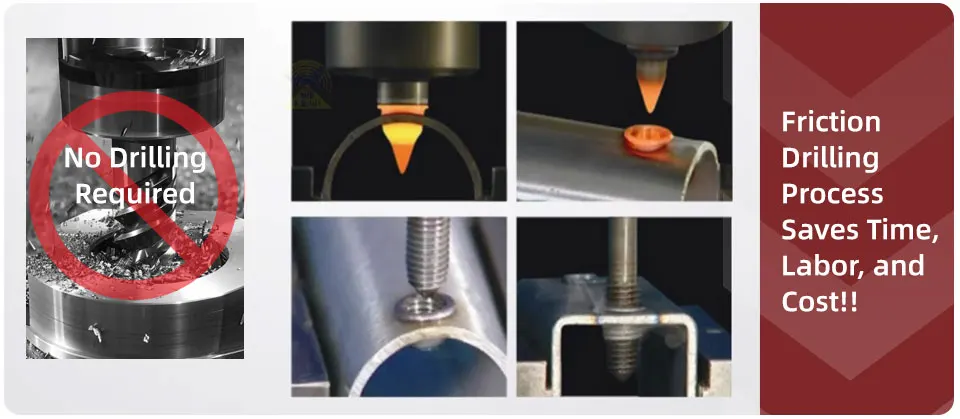

Still Using Traditional Drilling Processes?

Traditional Machining Processes Are Cumbersome, Costly, And Inefficient.

Stamped Nuts/Riveted Nuts/Welded Nuts/Drilling/Sanding/Grinding

Hot Melt Drilling Process Saves Time, Labor, and Cost

No Drilling Required

Conventional Welding Nut

Friction Drill Process Thread

Threaded bushings can be formed on the surface of thin materials in just a few seconds, requiring no additional materials. Only two steps are needed to produce high-precision products.

This effectively solves the problem of tapping threads in thin sheets, square tubes, and round tubes, greatly increasing connection strength. It eliminates the need for spot welding of cylinders, nuts, and washers, reducing processing steps, and offers high precision, thereby reducing product scrap rate and saving production costs.

Friction Drill Process Provides Very Hard Threads On The Surface Of Thin Materials

Very Effective In Replacing The Process Of Threaded Nuts And Rivet Nuts

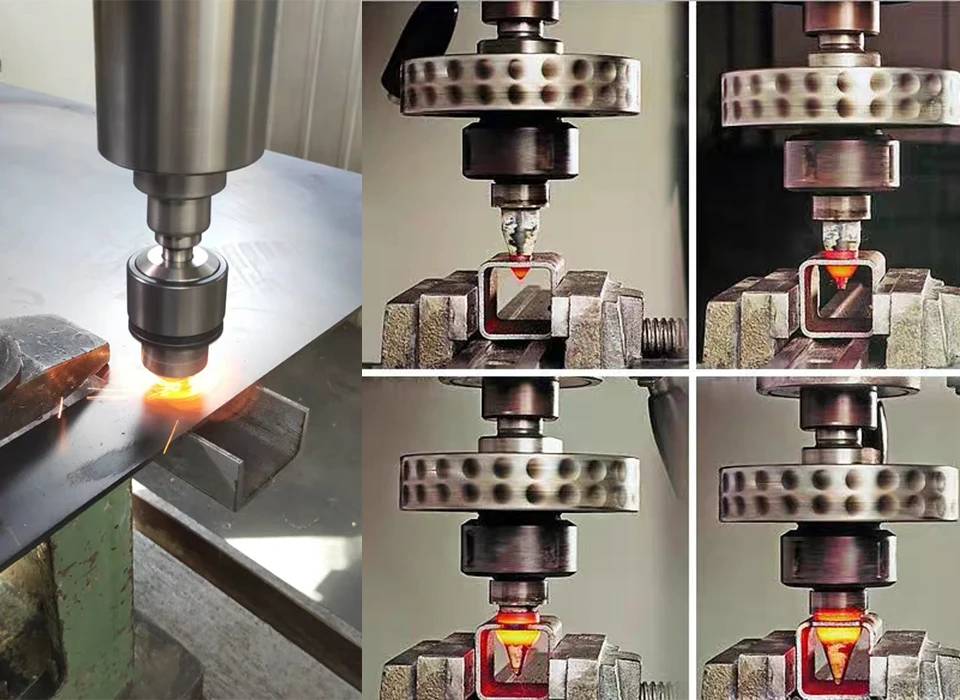

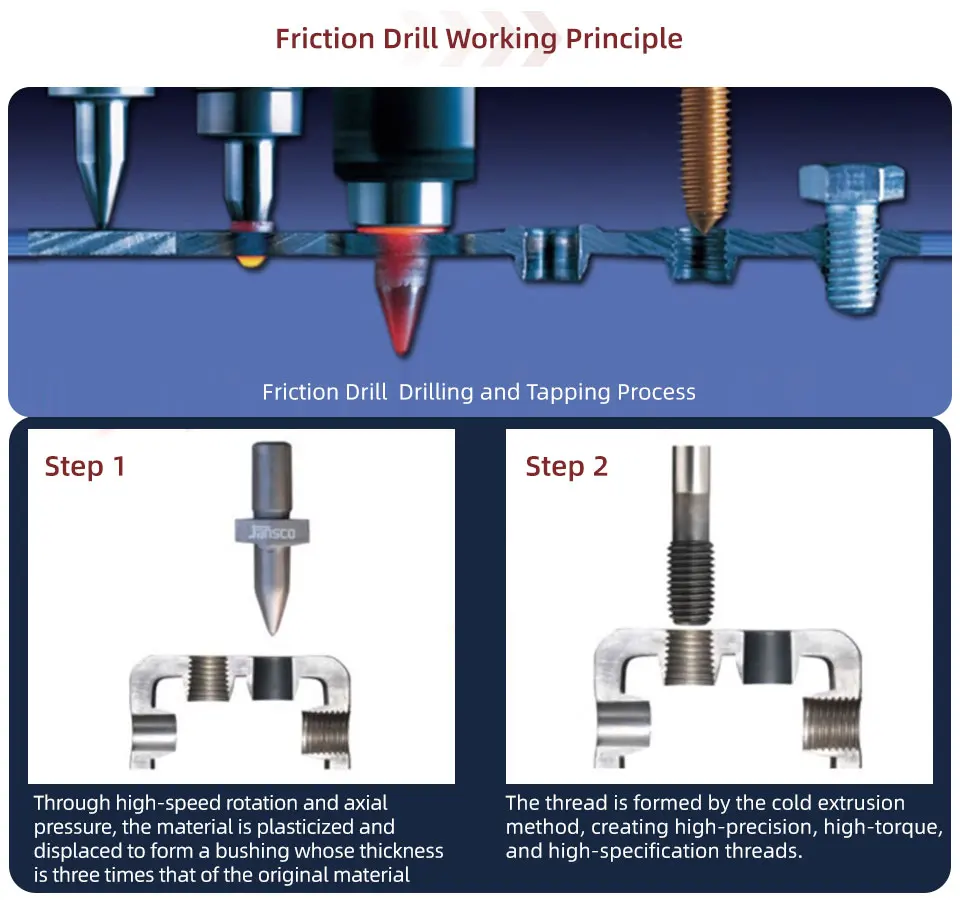

Friction Drill Working Principle

Friction Drill Drilling and Tapping Process

The Friction drilling process generates heat through high-speed rotation and axial pressure friction, causing material plasticization and displacement. It simultaneously drills holes and forms a bushing approximately three times thicker than the original material. Through the extrusion tapping process, it creates high-precision, high-strength threads on thin materials.

Step 1:Through high-speed rotation and axial pressure, the material is plasticized and displaced to form a bushing whose thickness is three times that of the original material

Step 2:The thread is formed by the cold extrusion method, creating high-precision, high-torque, and high-specification threads.

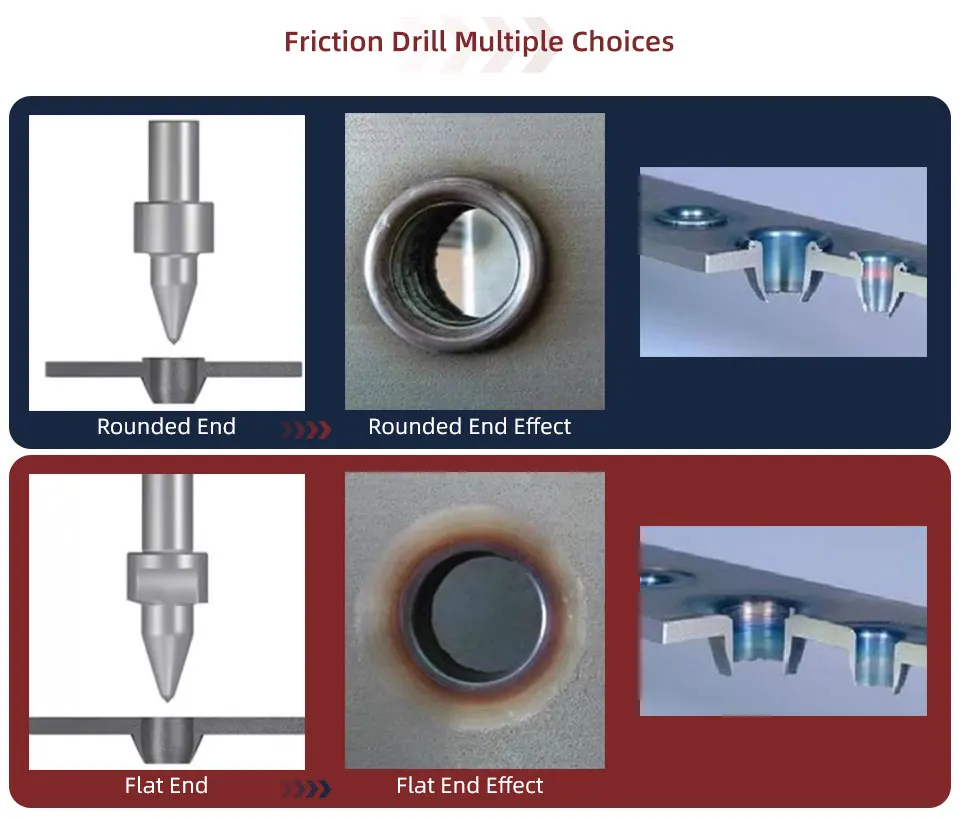

Friction Drill Multiple Choices

Rounded End-Rounded End Effect

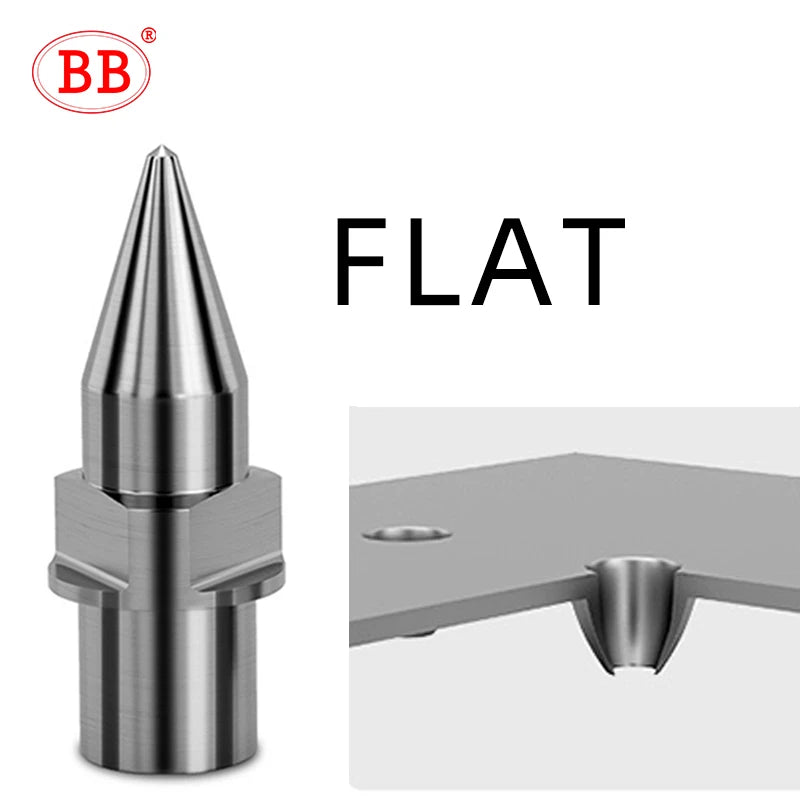

Flat End-Flat End Effect

Based on the surface requirements of the workpiece after Friction Drill penetration, there are two types of hot melt drills:

Rounded End (Standard Type): The Friction Drill penetrates the workpiece, forming a bushing while simultaneously creating a raised ring on the surface of the workpiece.

Flat End (Flush Type): The Friction Drill penetrates the workpiece, forming a bushing while simultaneously trimming off the raised ring, resulting in a smooth surface on the workpiece.

Friction Drill Auxiliary Tools

When used together, it makes your work easier.

01:Tool Holder:Using a standard tool holder will reduce the service life of the drill and the spring collet. Using a dedicated tool holder is more beneficial to extend the service life of the hot melt drill bit.

02:Tap:After drilling with a thermal drill, tapping can be done with a thermal tap, which can machine cold-formed threads.

Why choose extrusion taps:

The holes made by hot drilling are thinner due to the stretching of the hole wall. Using traditional cutting taps would damage the hole wall and reduce its strength. Therefore, it is recommended to use extrusion taps with hot drilling.

03:Friction Adhesive:When used with the hot melt adhesive, drilling becomes easier, reducing drill bit wear and effectively protecting the bit.

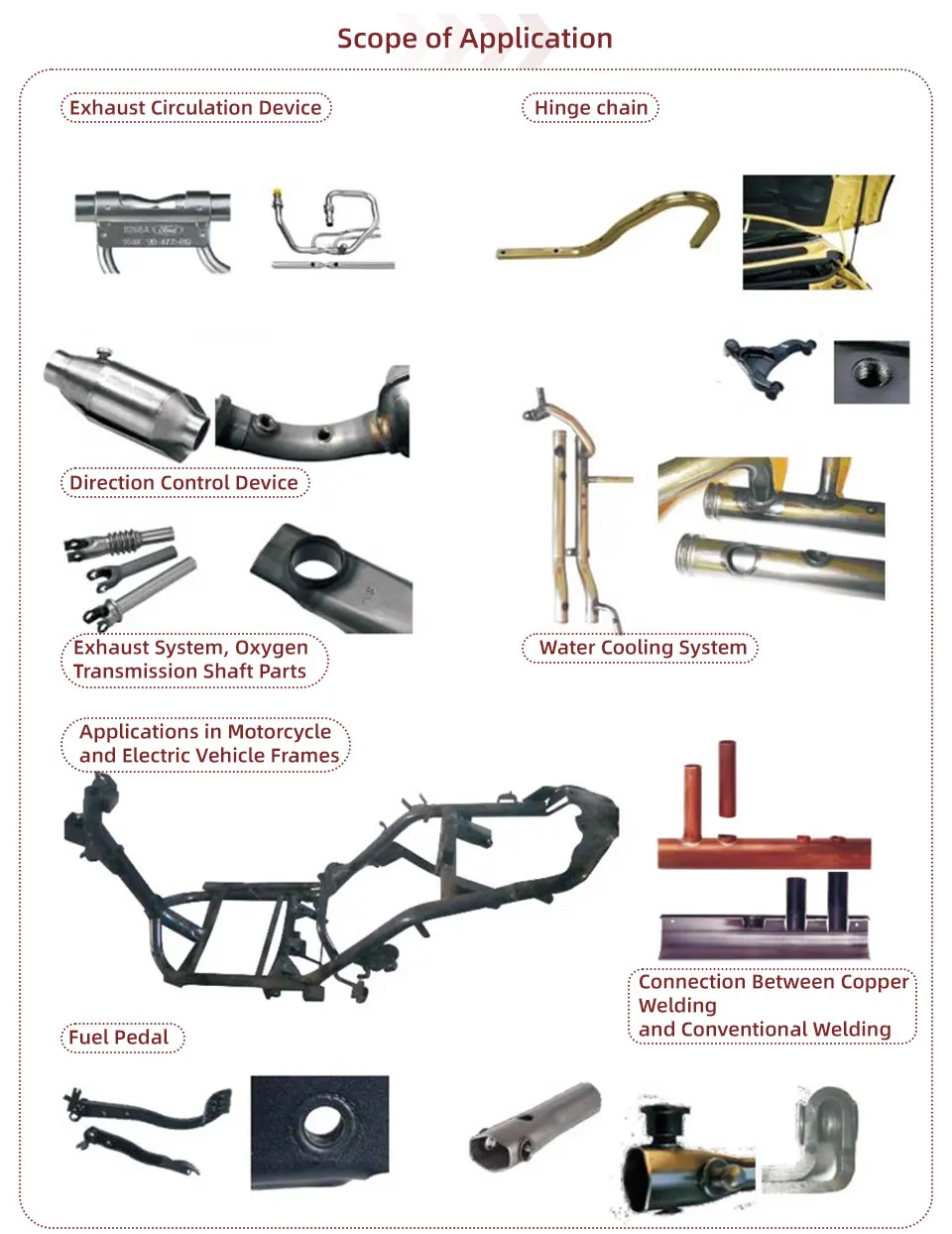

Scope of Application

Exhaust Circulation Device

Hinge Chain

Direction Control Device

Water Cooling System

Exhaust System, Oxygen Transmission Shaft Parts

Applications in Motorcycle and Electric Vehicle Frames

Fuel Pedal

Connection Between Copper Welding and Conventional Welding

High-Quality Material, Fast Drilling

The Sum Of The Formed Annular Boss And Cylinder Height Exceeds Three Times The Thickness Of The Original Material, Able To Withstand Very Large Torque And Tension; Capable Of Replacing Traditional Welding And Rivet Nut Processes.

Increase Work Efficiency

Processing cycle time only takes 2~6 seconds; save your processing time and reduce your costs.

High Precision More Accurate

High precision and high strength - the holes drilled have higher precision; greatly improve your product quality.

Convenient, Detailed Environmental Protection

Clean and environmentally friendly, the drilling process does not produce or produces less chips.

1. Improve production efficiency.

Fast Drilling, fast bushing forming, the whole process only takes 2-6 seconds. The molding bushing can directly squeeze the thread; Replace the welding nut or riveting nut with complicated production process.

2. Improve product quality

BB friction drill simplifies the process flow and is easy to operate; The precision of hole position is high; The screw obtained by extrusion has high tensile strength and torsion resistance.

3. Reduce production costs

The operation is simple and easy to master, and there is no need to add equipment to replace expensive welding procedures.

4. Clean and environmentally friendly, without debris.

5. Save materials.

The high-speed rotating BB Friction Drill contacts the surface of the workpiece and fricts with the metal surface to produce high temperature (600 degrees) or above.

Cutting Conditions

HI, welcome to BB official store.

-We are professional manufacturer ,development and production of machining tools.

-We provide various tools for you . You can follow us and see more.

-You have free choice of collocation, pick different specifications and other tools in our store to you cart and pay them together. We will send the products you have picked as a package.

-Take an additional 5%~10% off when you buy more.

SHIPMENT

-We have already paid 80% of delivery cost .

-Orders processed timely after the payment verification.We ship products within 3 working days.

-The trade is cross-border, and Airmail is cheapest post which take a long time for delivery.If you need the item urgently ,please choose Express way.

-If you have not received your shipment within 60 days from payment, please contact us. We will track the shipment and get a reply to you as soon as possible.

We sincerely hope that BB tools will meet your full requirements. Please enjoy your online shopping.