BB Tool

BB Holder for Drill Thermal Friction Hot Melt Cooling Tool ER20 ER25 ER32 Stable Precision Workpiece Holding

BB Holder for Drill Thermal Friction Hot Melt Cooling Tool ER20 ER25 ER32 Stable Precision Workpiece Holding

Impossible de charger la disponibilité du service de retrait

Partager

BB Friction Drill Holder

*Hoder does not contain a collet

Robust Cooling Durable and Long-Lasting

*No Insert

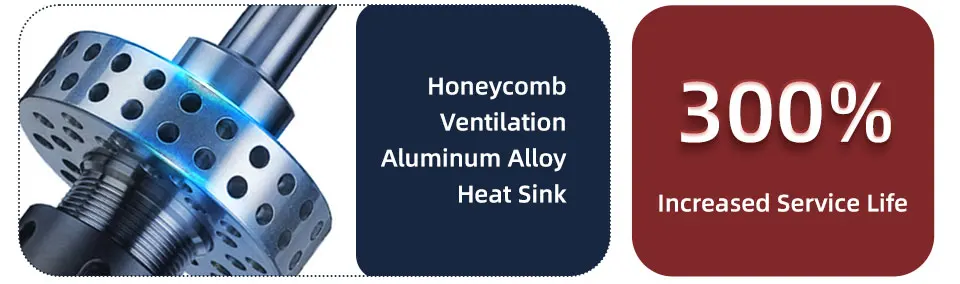

Honeycomb Ventilation Aluminum Alloy Heat Sink

Utilizes a special aluminum alloy material with integrated cooling fins or discs to rapidly dissipate heat generated during operation, preventing overheating of the tool holder and extending its service life.

300% Increased Service Life

High-Precision Compatibility, Versatile Application

*No Insert

Elastic Collet Anti-Slip Design

Features a precision clamping mechanism that ensures concentricity of the thermdrill bit during high-speed rotation, enhancing machining accuracy and reducing errors.

0.01mm Ultra-High Concentricity: ER Collet Chuck with Anti-Slip Design, Compatible with 2~50.8mm Drill Bits.

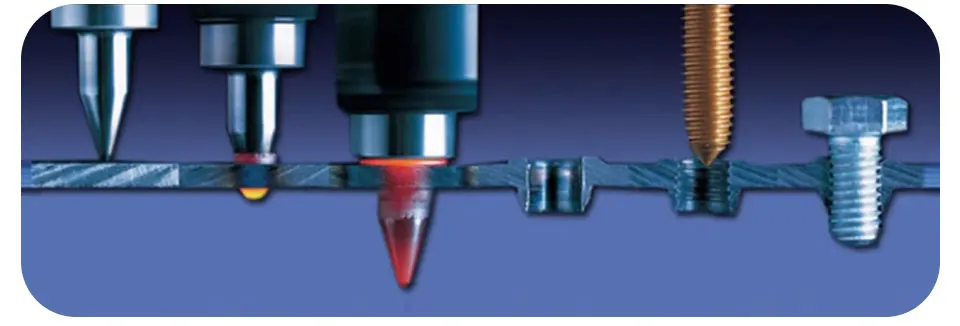

Clean Forming Time and Labor Saving

One-shot Forming Threaded Bushing, Strength Increased by 5 Times, No Secondary Tapping Required

Extensive Compatibility and Adaptability

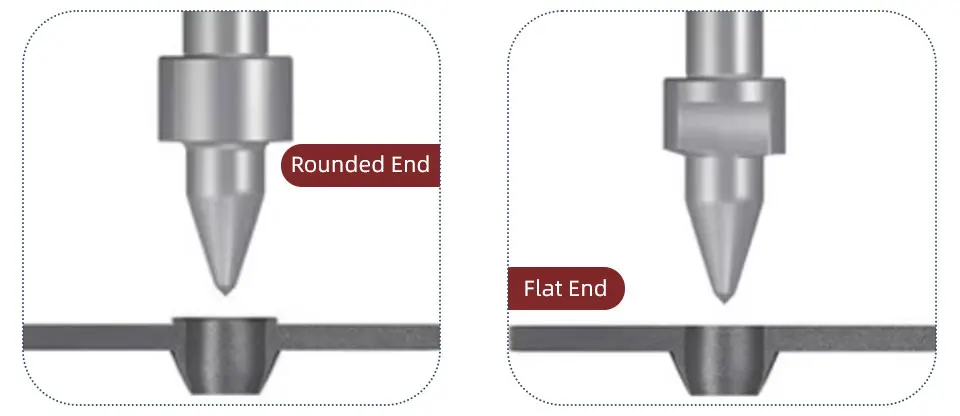

Rounded End/Flat End

Compatible with a Variety of Hot Melt Drill Bits (Such as Round, Flat, and Special Shaped Bits), Suitable for Processing Different Specifications of Metal Sheets and Tubes, Meeting Your Diverse Machining Needs.

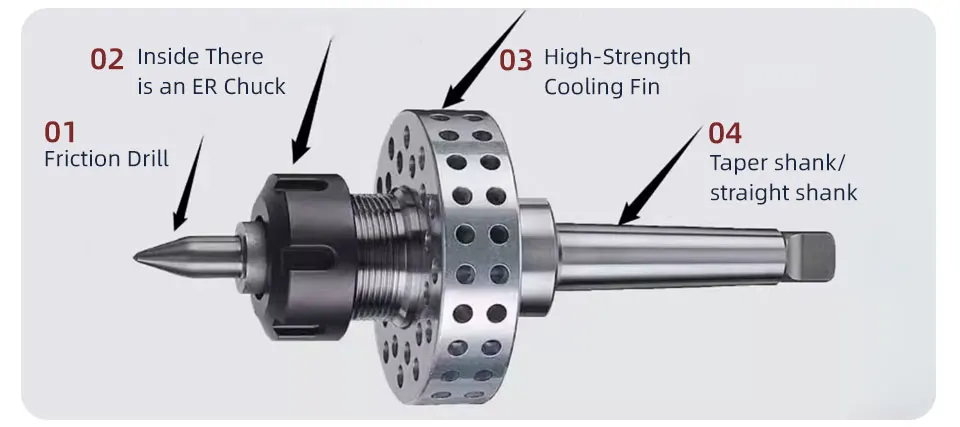

Friction Drill Holder Auxiliary Tools

01:Friction Drill:Using a standard tool holder will reduce the service life of the drill and the spring collet. Using a dedicated tool holder is more beneficial to extend the service life of the hot melt drill bit.

02:ER Collet Chuck:After drilling with a thermal drill, tapping can be done with a thermal tap, which can machine cold-formed threads.

Why choose extrusion taps:

The holes made by hot drilling are thinner due to the stretching of the hole wall. Using traditional cutting taps would damage the hole wall and reduce its strength. Therefore, it is recommended to use extrusion taps with hot drilling.

03:High-Strength Cooling Fin:A special aluminum alloy heat dissipation disk rapidly disperses the heat produced, ensuring that the equipment’s spindle is protected from damage caused by excessively high temperatures.

04:Handle:Manual Drills: MT2, MT3 Morse Taper or cylindrical shanks (Such as Ø16, Ø20mm).

CNC Machining Centers: BT30, BT40, HSK A-63 interfaces.

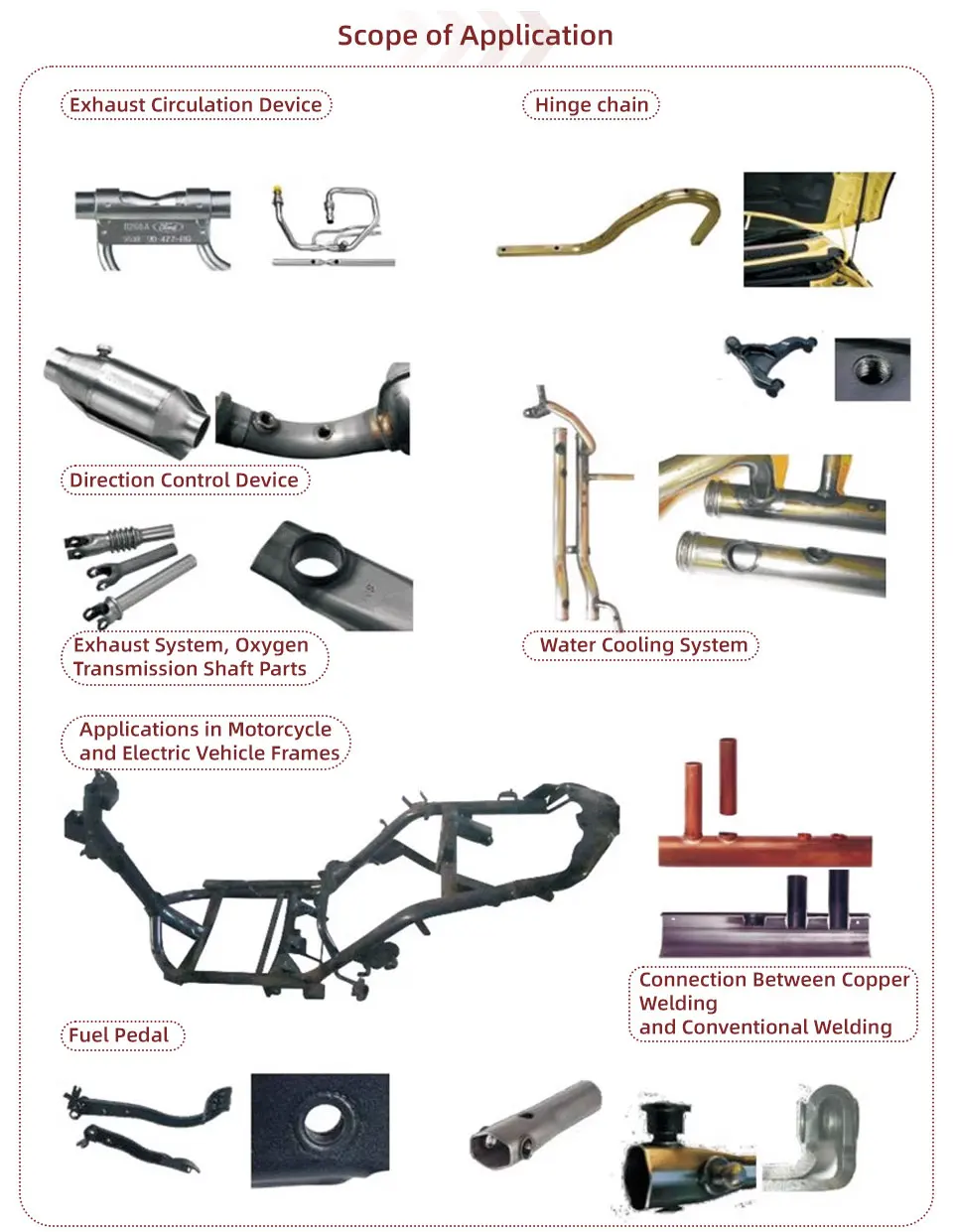

Scope of Application

Exhaust Circulation Device

Hinge Chain

Direction Control Device

Water Cooling System

Exhaust System, Oxygen Transmission Shaft Parts

Applications in Motorcycle and Electric Vehicle Frames

Fuel Pedal

Connection Between Copper Welding and Conventional Welding

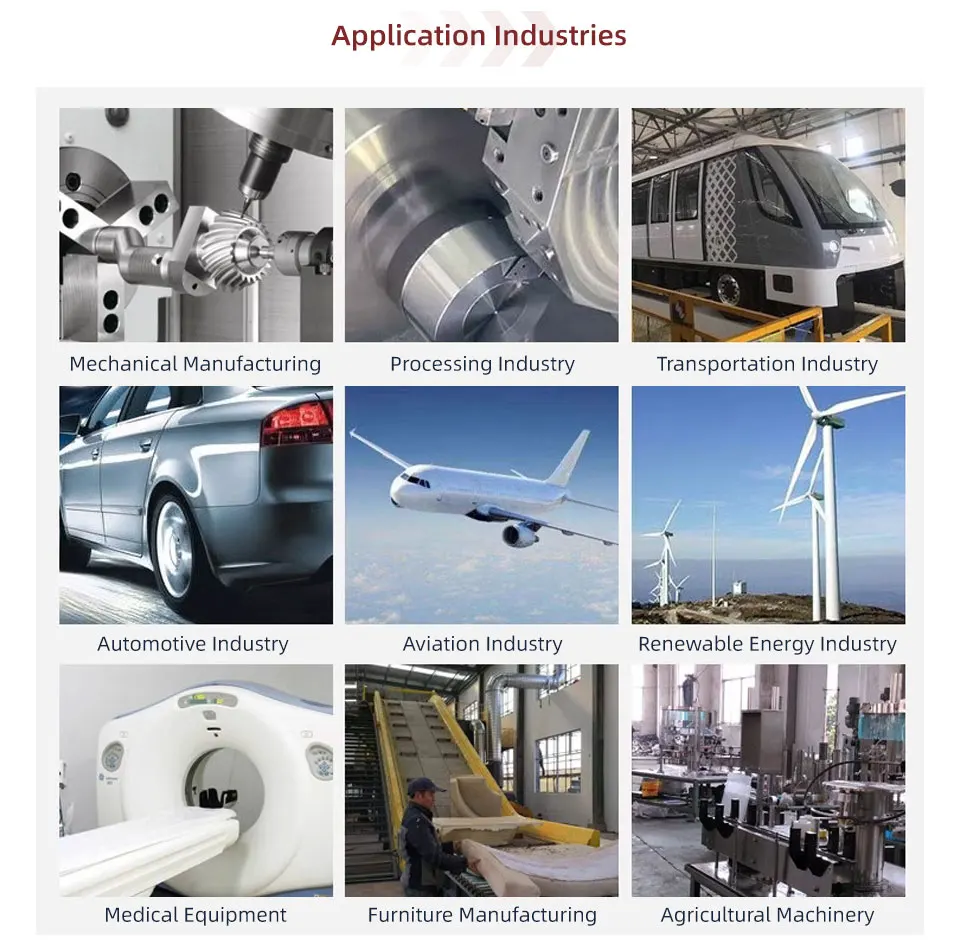

Application Industries

Mainly used in the manufacturing fields of AI intelligent robots, drones, automobiles, aerospace, household appliances, mold, furniture industry, agricultural machinery, medical devices, etc.

Mechanical Manufacturing -

Processing Industry -

Transportation Industry -

Automotive Industry -

Aviation Industry -

Renewable Energy Industry -

Medical Equipment -

Furniture Manufacturing -

Agricultural Machinery -