BB Tool

BB Machine Tap Long Length HSS TiN Straight Flute Fluteless Spiral Flute Thread Tool M2-M12

BB Machine Tap Long Length HSS TiN Straight Flute Fluteless Spiral Flute Thread Tool M2-M12

Impossible de charger la disponibilité du service de retrait

Partager

BB Long Length Tap

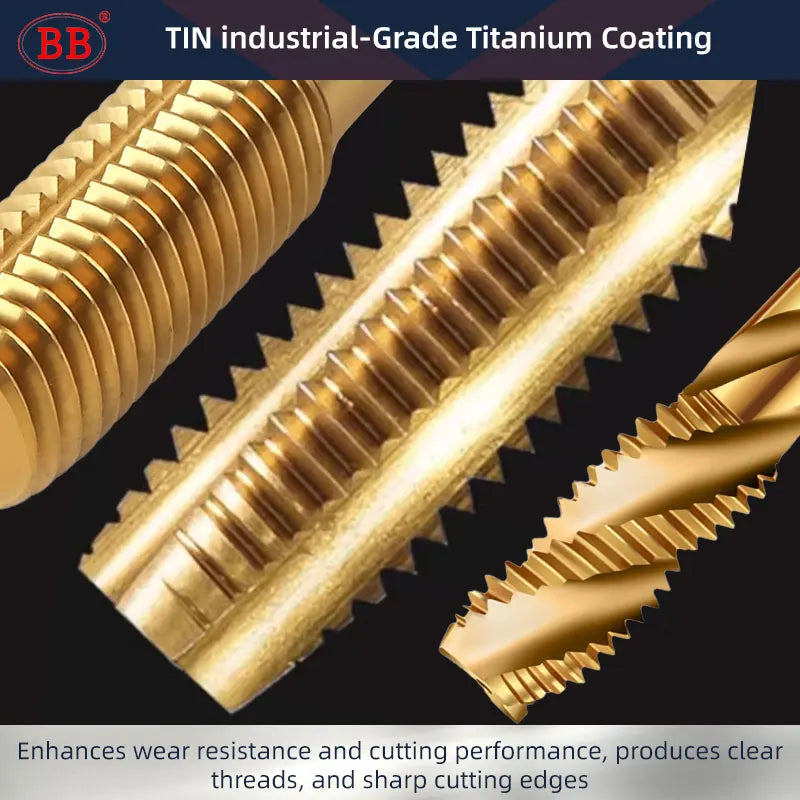

TIN industrial-Grade Titanium Coating

Enhances wear resistance and cutting performance, produces clear threads, and sharp cutting edges

Optimized Flute Design for Smooth Threading Without Burrs

Large flute, ample chip space, excellent chip evacuation, improves threading quality

Sturdy Square Shank / Wide Application

Universal square shank design, secure clamping without slippage, suitable for various chucks

High-Speed Steel Material/Sharp and Wear-Resistant

Made of HSS high-speed steel, it ensures the hardness and toughness of the high-speed steel, effectively improving the overall machining quality

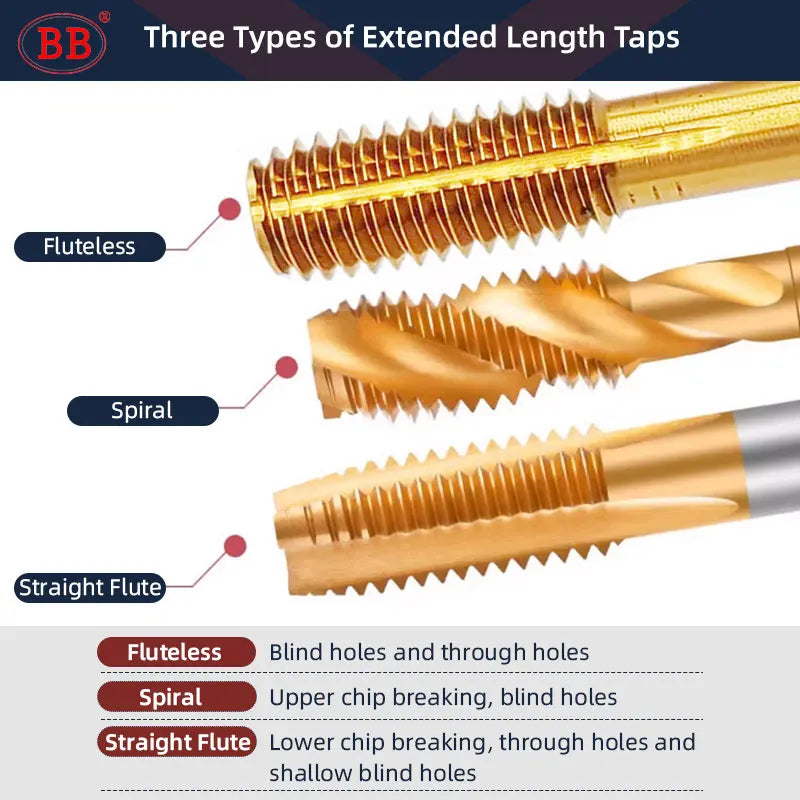

Three Types of Extended Length Taps

Fluteless:Blind holes and through holes

Spiral:Upper chip breaking, blind holes

Straight Flute:Lower chip breaking, through holes and shallow blind holes

Three Types of Tap Usage Methods

Straight Flute

Performance:Lower chip breaking, through holes

Advantages:Excellent heat dissipation, superior through-hole effects

Features:Can tap up to the bottom of the through-hole without residual cutting, smooth chip evacuation, easily engages with the bottom hole, and provides good cutting performance

Purpose:For cutting materials that form a continuous curve

Through-Hole/Shallow Blind Hole Machining:Holes with axial slots on the inner wall

Spiral

Performance:Upper chip breaking, blind holes

Advantages:Strong cutting ability, wide range of applications

Features:Edge inclination slots, no chip clogging, resistance to chipping damage, strong cutting performance

Purpose:For cutting materials that form a continuous curve

Blind Hole Machining:Holes with axial slots on the inner wall

Fluteless

Performance:Utilizes the principle of metal plastic deformation

Advantages:Suitable for both through holes and blind holes, with a long service life

Features:Can tap to the bottom of the blind hole without residual cutting, chipless machining, easily engages with the bottom hole, and provides good cutting performance

Purpose:Materials with low hardness and high plasticity

Blind Hole/Through Hole Machining:Holes with axial slots on the inner wall

Comparison of Tap Shank Parts

Different Dimensions for Shank and Head

Above M8 is Flat Head

Below M8 is Pointed Head

High Hardness/Drilling Nemesis

Extended titanium-coated taps are more suitable for harder materials such as castings and stainless steel

Scope of Application

Stainless steel, carbon steel, die steel, aluminum, copper, and other non-hardened and quenched metals

Compatible Machine Models

Tapping Machine

Drilling and Tapping Machine

CNC Milling Machine

Tapping Speed Reference

Product Selection Reference:

01:Generally , the speed of tapping will affect the selection of tapping speed due to the cuttingmaterial , bottom hole shape , tapping type , tapping material , surface treatment type , cutting oiltype , tapping machine type and ability , and other use conditions , so please carefully considerhe selection

02:The following table shows the reference table of cutting speed of various cut materials undernormal conditions . Please refer to the data on the table and the cutting conditions of the cuttingmachine itself to select the appropriate cutting