BB Tools

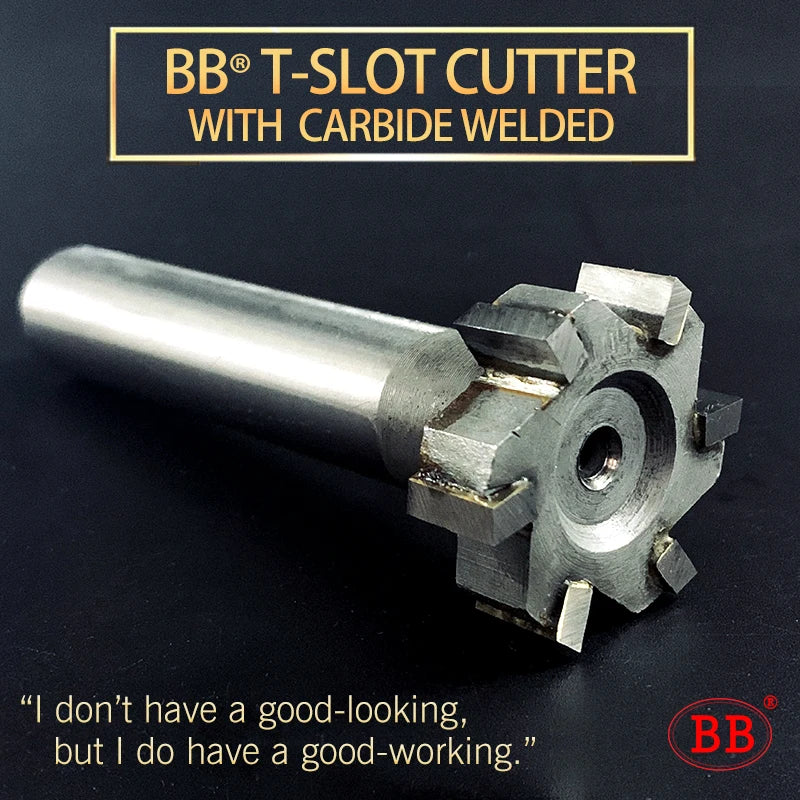

BB T Slot Milling Cutter Tipped Carbide insert

BB T Slot Milling Cutter Tipped Carbide insert

Couldn't load pickup availability

Share

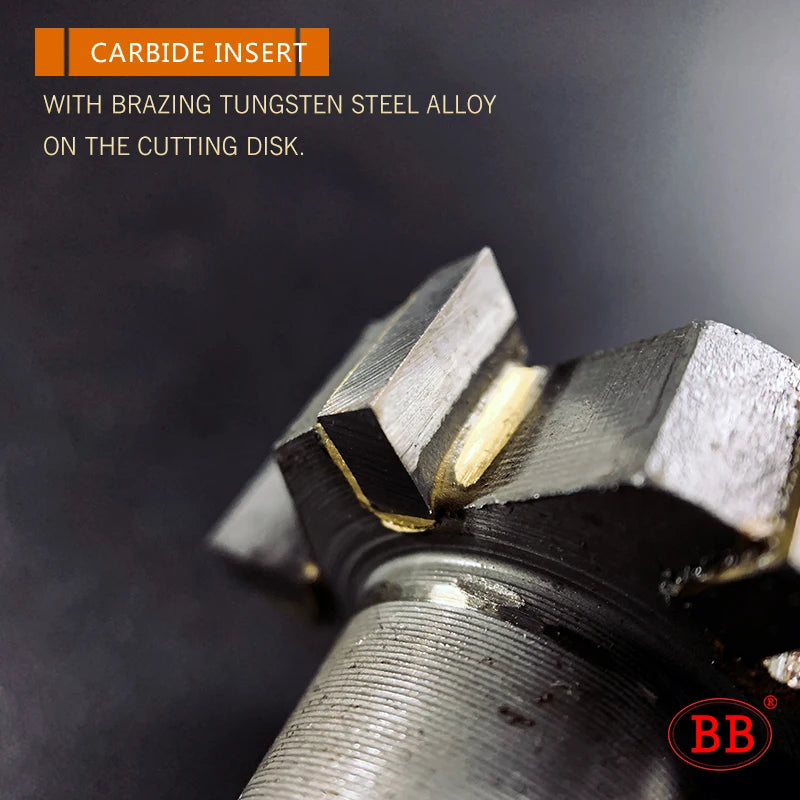

精密钎焊工艺 - 硬质合金与刀体结合强度高,抗冲击不崩裂 Precision Brazing Process - High bonding strength, impact resistant

加粗抗震刀体 - 合金钢材质,大悬伸加工仍保持稳定 Reinforced Anti-Vibration Body - Stable performance even with large overhang

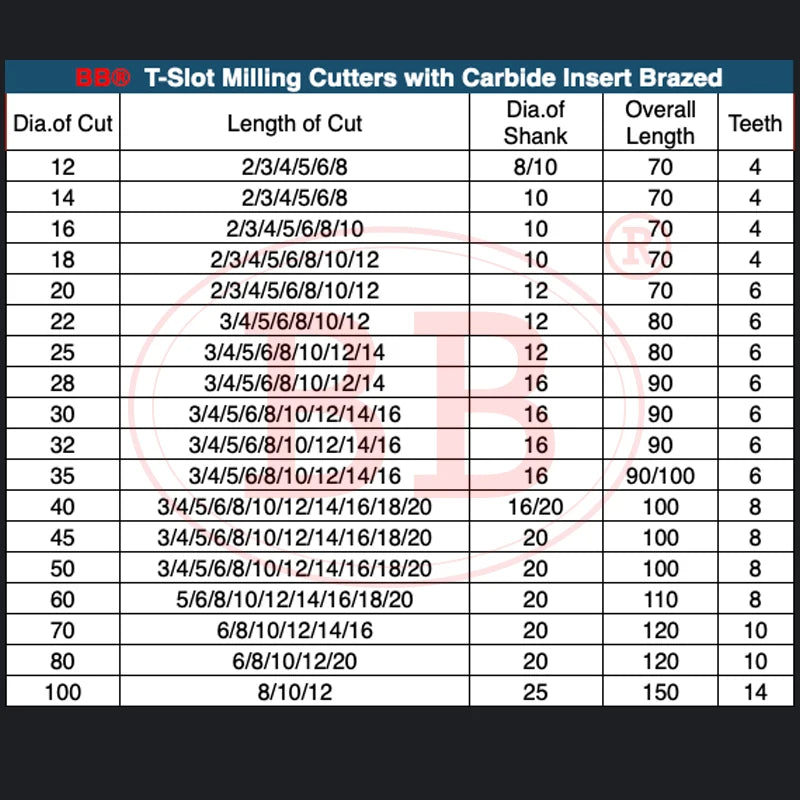

全规格覆盖 - 从12mm到80mm标准规格库存立即可发 Complete Size Range - D12 to D80 in stock, ready to ship

经济高效 - 比整体合金成本降低40% Cost Effective - 40% savings vs solid carbide

柄部末端倒角 - 精准15°倒角处理,实现快速换刀并保护夹套内壁 Shank End Chamfer - 15° precision chamfer for quick tool changes and collet protection

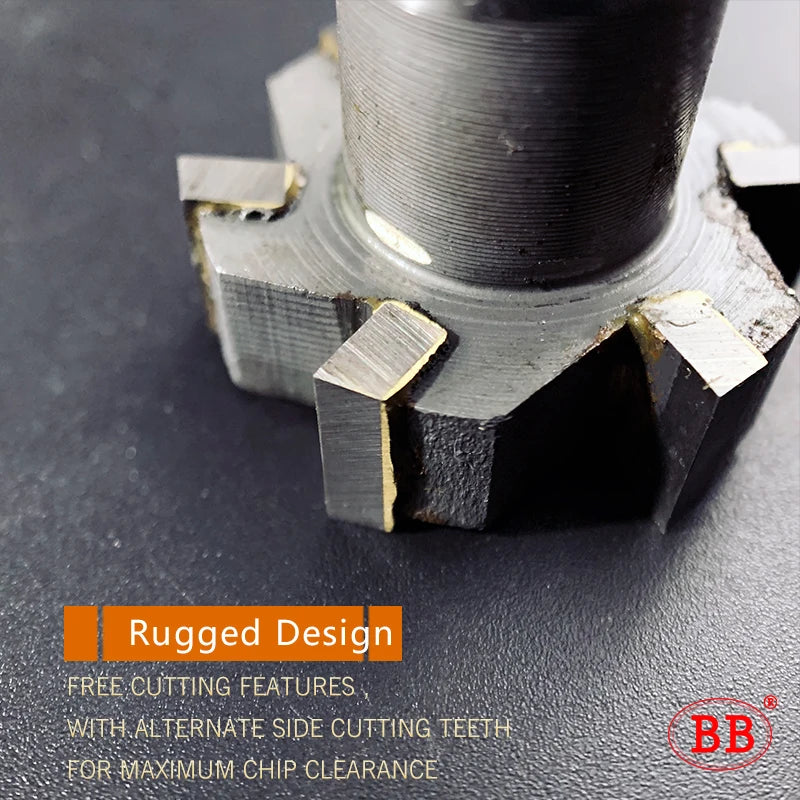

双优化几何角度 - 前角与后角经磨削,切削轻快排屑顺畅 Dual-Optimized Geometry - Ground rake & clearance angles for smooth cutting

定制能力 - 接受非标 Customization Service

适用材料: 钢、不锈钢、铸铁、铝合金 Applications: Steel, Stainless, Cast Iron, Aluminum

| 特性 / Aspect | 描述 / Description |

|---|---|

| 结构 / Structure | 合金钢刀体 + 钎焊式硬质合金刀头 / Alloy Steel Body + Brazed Carbide Tip (typically on cutting edges only) |

| 核心优势 / Key Advantage | 性价比高,耐磨性优于高速钢 / Cost-effective, with wear resistance far superior to HSS. |

| 适用场景 / Application | 中小批量T型槽加工,经济之选 / Small to medium batch T-slot machining; an economical choice. |

| 局限性 / Limitation | 抗冲击性较弱,难重磨 / Lower impact resistance, difficult or impossible to regrind. |

Troubleshooting

问题 / Problem - 可能原因 / Possible Cause

合金头崩掉 / Tip Breaks - 进给或切深过大 / Feed or depth of cut too high

快速磨损 / Rapid Wear - 线速度过高 / Cutting speed (Vc) too high

振动异响 / Vibration & Noise - 参数过高或悬伸长 / Parameters too aggressive or tool overhang too long

排屑不畅 / Poor Chip Evacuation - 冷却液不足 / Insufficient coolant flow

HI, welcome to BB official store.

-We are professional manufacturer ,development and production of milling tools.

-We provide various tools for you . You can follow us and see more.

-You have free choice of collocation, pick different specifications and other tools in our store to you cart and pay them together. We will send the products you have picked as a package.

-Take an additional 5%~10% off when you buy 10 pieces or more.