BB Tool

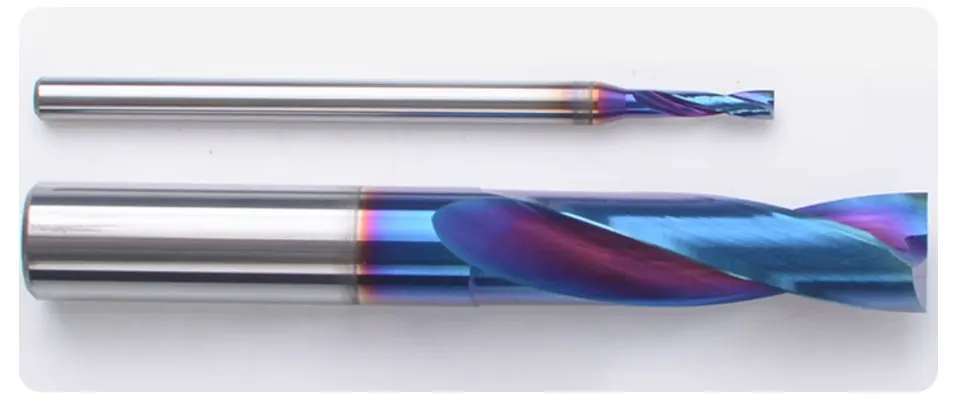

BB Flat Bottom Drill Bit Long Length 2mm-12mm Carbide Hole Drilling Tool BK2055 BL2060

BB Flat Bottom Drill Bit Long Length 2mm-12mm Carbide Hole Drilling Tool BK2055 BL2060

Couldn't load pickup availability

Share

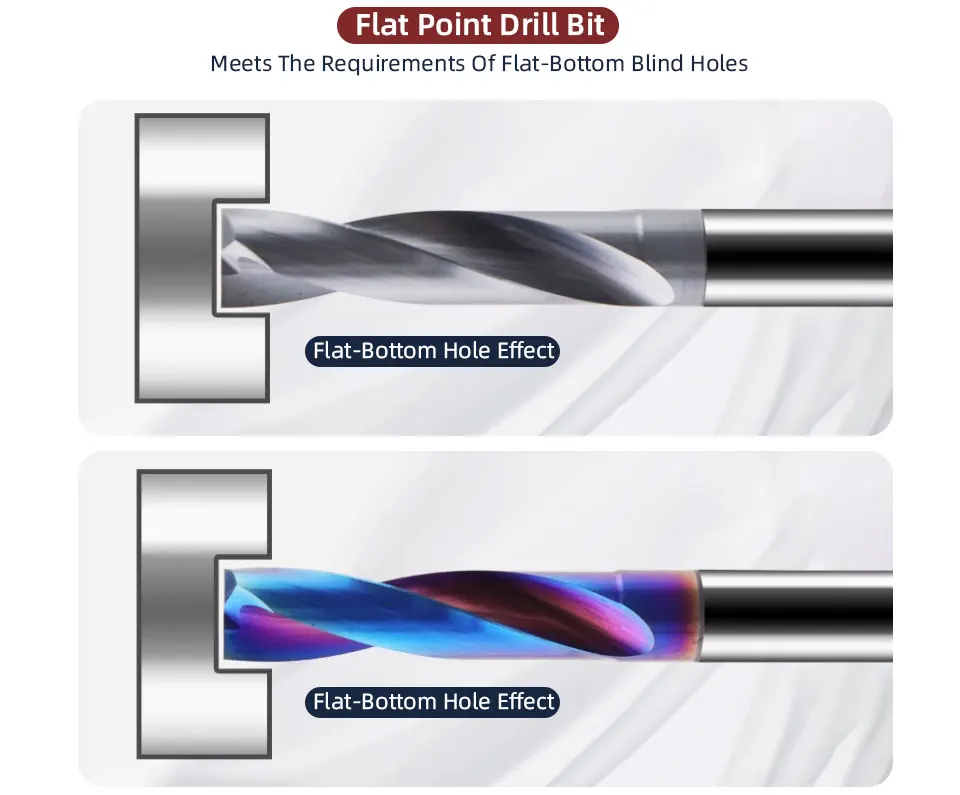

Flat Bottom Drill

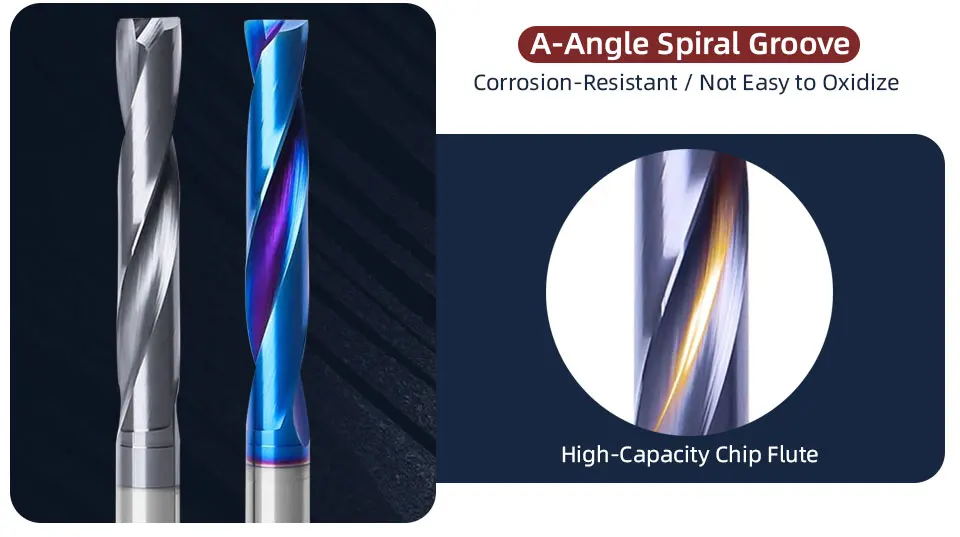

A-Angle Spiral Groove

Corrosion-Resistant / Not Easy to Oxidize

The A-angle geometry reduces cutting forces, expedites chip flow, enhances structural rigidity, and provides superior vibration damping, minimizing tool chipping and extending tool life.

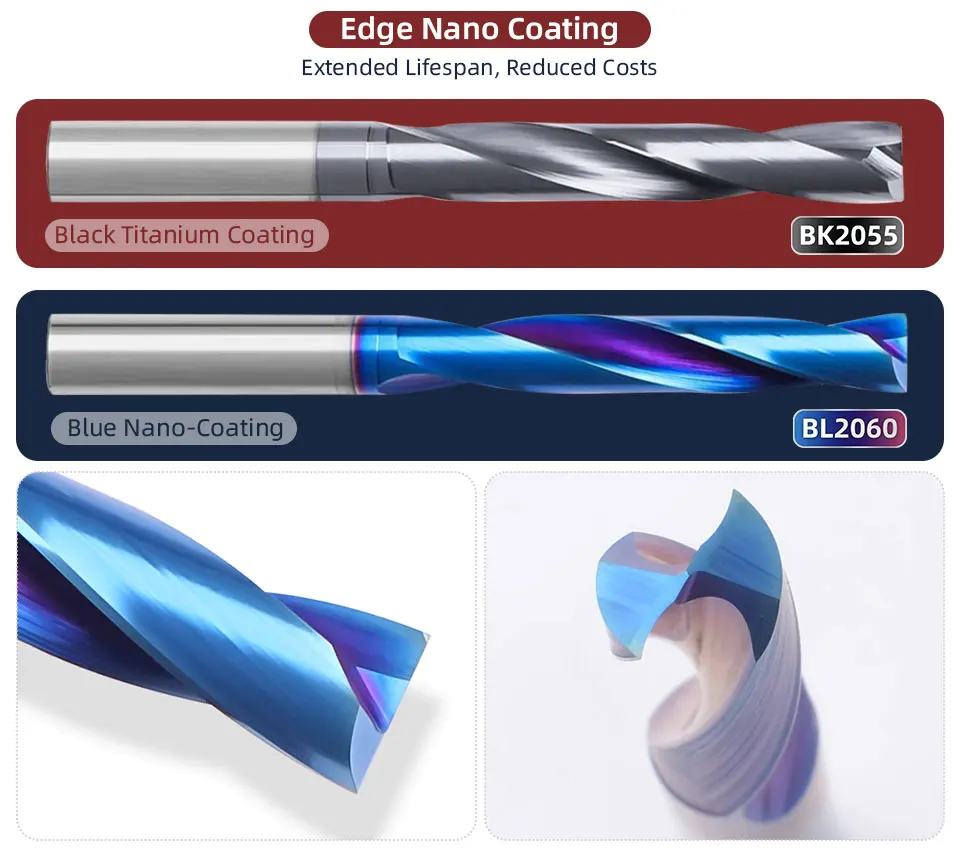

Edge Nano Coating

Extended Lifespan, Reduced Costs

Advanced Multi-Coating Technology: Enhances Milling Cutter Performance, Ensuring Exceptional Wear Resistance and Extended Tool Life for Maximum Cost Savings.

BK2055:Black Titanium Coating

BL2060:Blue Nano-Coating

180-Degree Flat-Head Edge

No Deflection, Small Hole Expansion

edge Passivation Treatment, Resulting in Higher Surface Finish of the Tool, While Enhancing Rigidity and Sharpness for Smoother Cutting

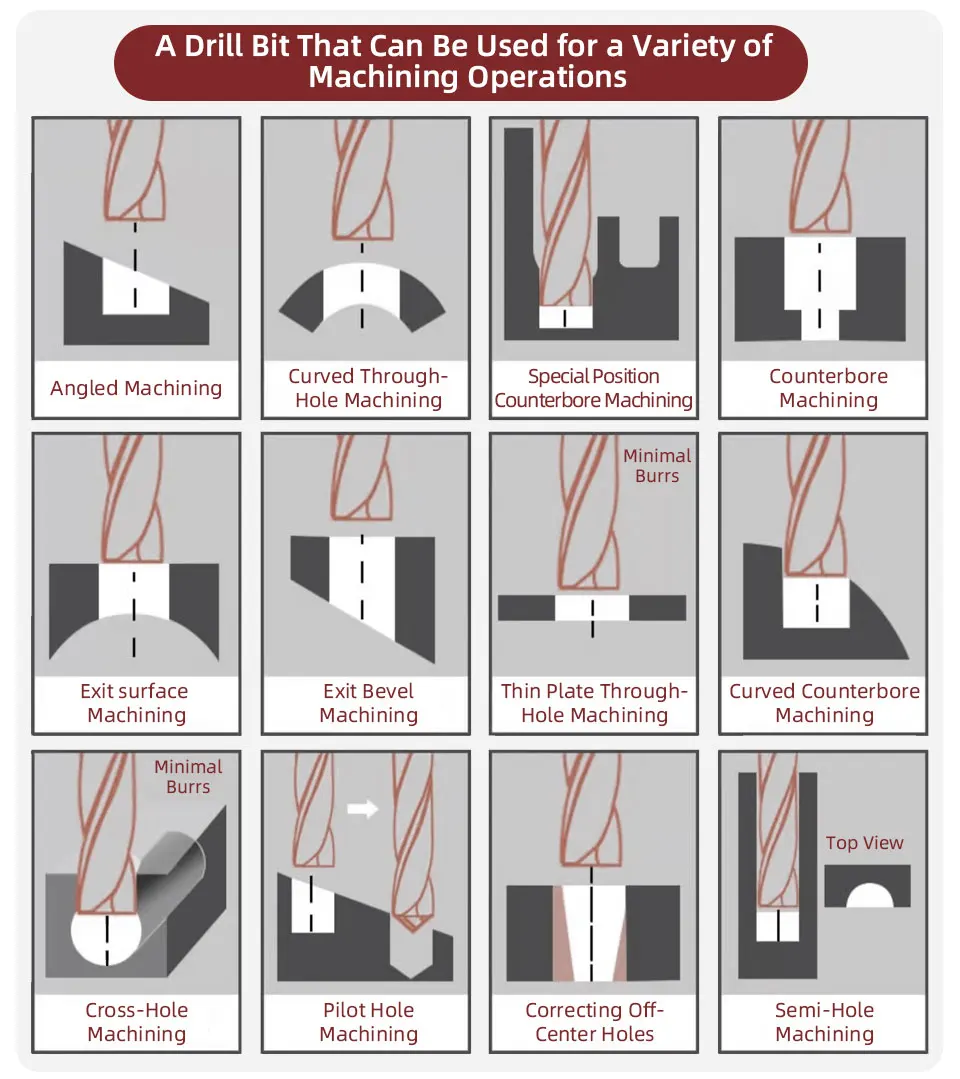

A Drill Bit That Can Be Used for a Variety of Machining Operations

Capable of handling a variety of machining conditions such as counterbores, angled surfaces, and cross holes.

Angled Machining

Curved Through-Hole Machining

Special Position Counterbore Machining

Counterbore Machining

Exit surface Machining

Exit Bevel Machining

Thin Plate Through- Hole Machining

Curved Counterbore Machining

Cross-Hole Machining

Pilot Hole Machining

Correcting Off-Center Holes

Semi-Hole Machining

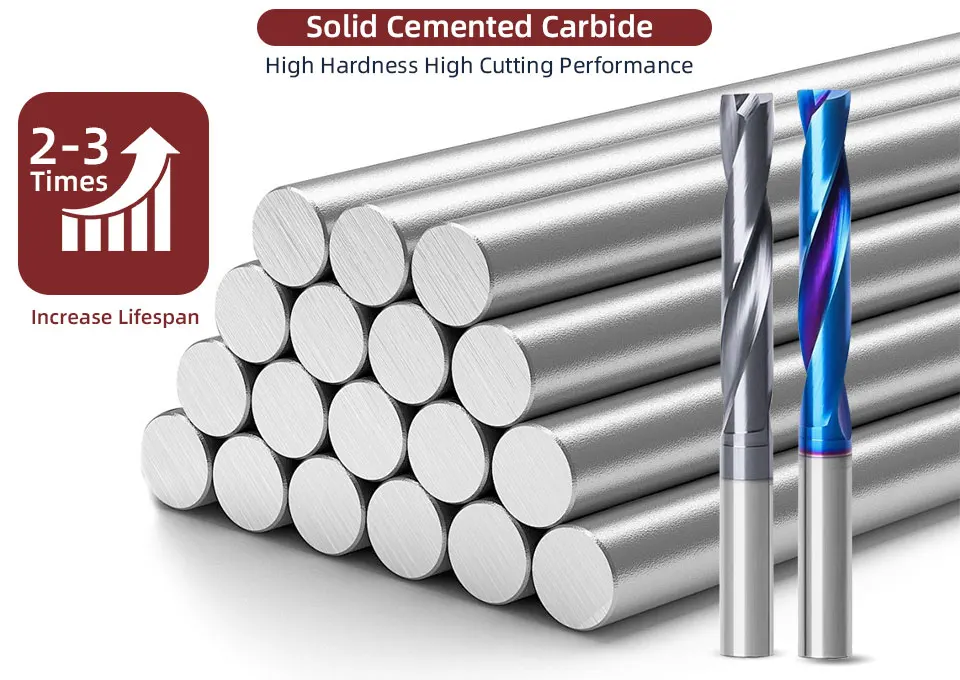

Solid Cemented Carbide

High Hardness High Cutting Performance

Increase Lifespan 2-3 Times

Utilizing micro-grain carbide substrate, it possesses enhanced wear resistance and strength, specifically designed for high-hardness high-speed cutting applications.

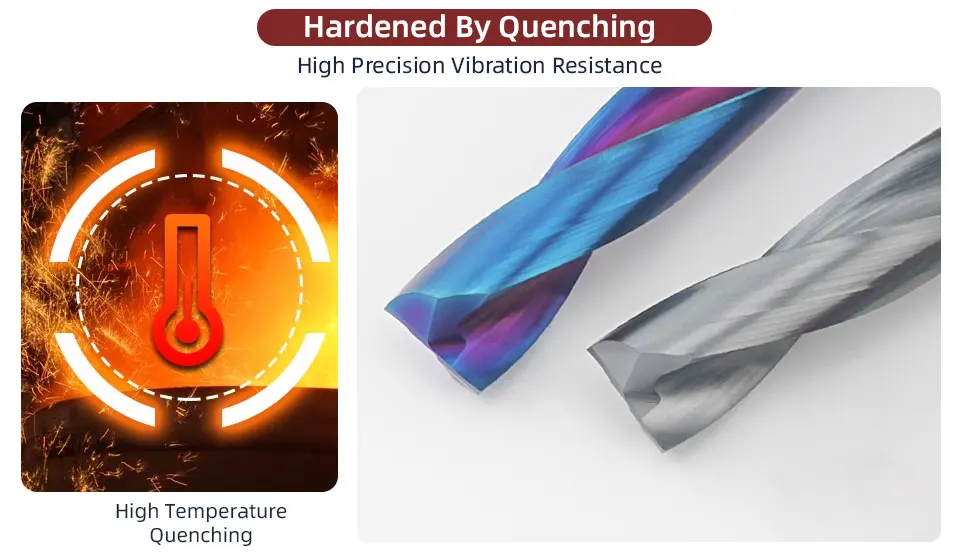

Hardened By Quenching

High Precision Vibration Resistance

High Temperature Quenching

Good Quenching Penetration,Resistant To Multiple Impacts

Excellent Low Temperature Impact Toughness,Sturdy And Durable,

Can Improve Cutter Head Service Life And Vibration Resistance

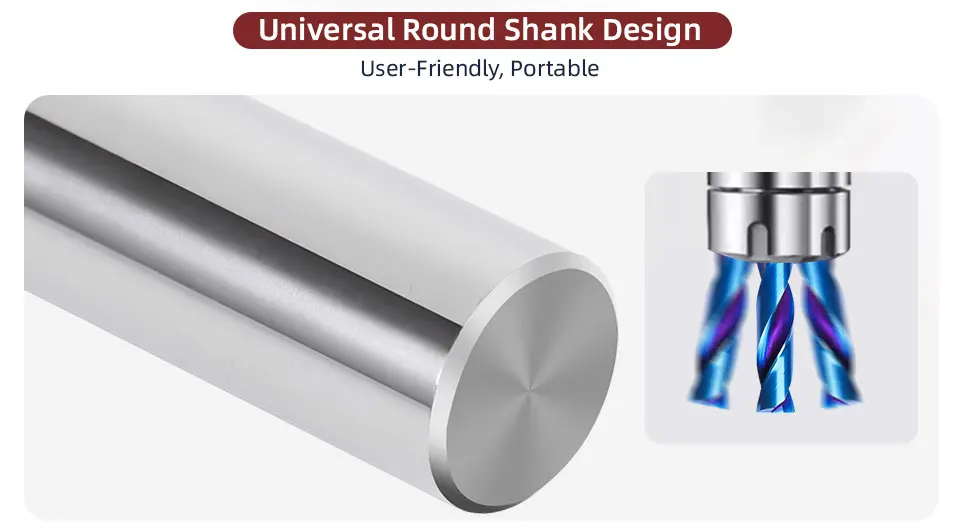

Universal Round Shank Design

User-Friendly, Portable

The handle has a chamfered design, making it easier to clamp

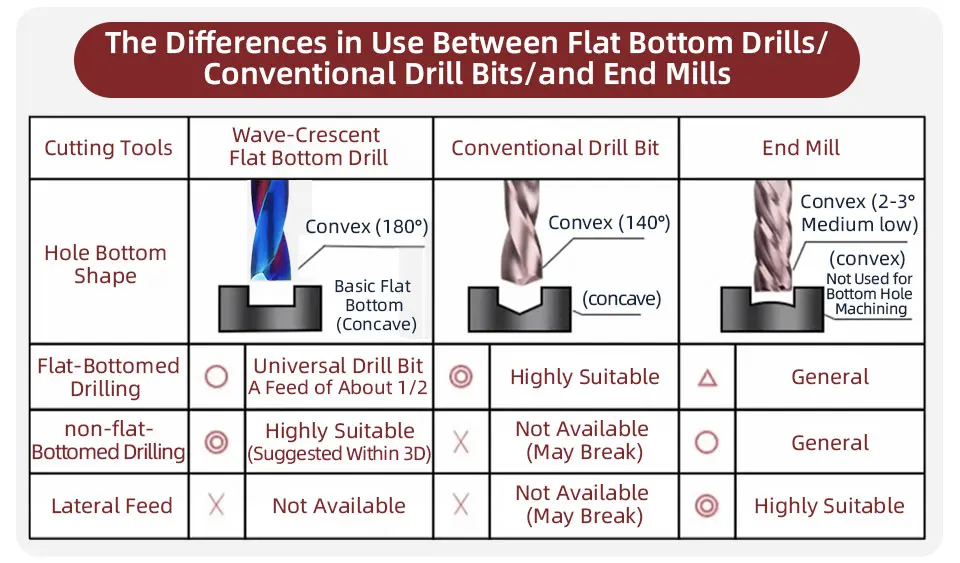

The Differences in Use Between Flat Bottom Drills/ Conventional Drill Bits/and End Mills

Cutting Tools:

Hole Bottom Shape

Flat-Bottomed Drilling

non-flat-Bottomed Drilling

Lateral Feed

Wave-Crescent Flat Bottom Drill:

Convex (180°) 、Basic Flat Bottom (Concave)

Universal Drill Bit A Feed of About 1/2

Highly Suitable (Suggested Within 3D)

Not Available

Conventional Drill Bit:

Convex (140°)、 (concave)

Highly Suitable

Not Available (May Break)

End Mill:

Convex (2-3° Medium low)、(convex)、Not Used for Bottom Hole Machining

General

Highly Suitable

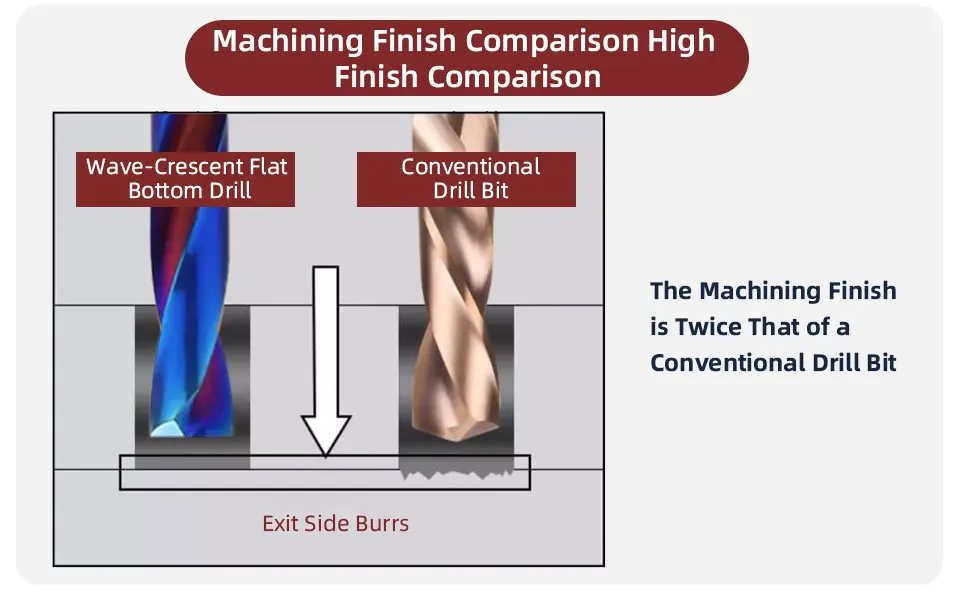

Machining Finish Comparison High Finish Comparison

The Machining Finish is Twice That of a Conventional Drill Bit

Wave-Crescent Flat Bottom Drill

Conventional Drill Bit

Exit Side Burrs

Applicable Materials

Born for Metal Drilling

Suitable for stainless steel, die steel, sheet steel, etc.

Applicable Machines

Drilling Equipment

Machining Center

Engraving Machine