BB Tool

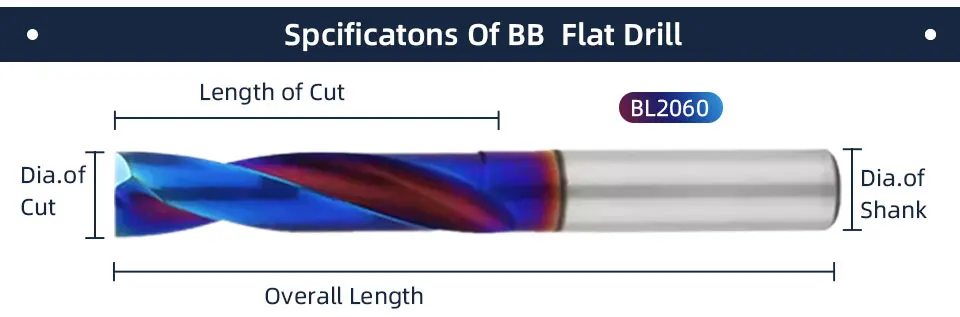

BB Flat Drill 180 Degree CNC Drilling Tool Coated Solid Carbide for Metal Alloy Steel Hole BL2060

BB Flat Drill 180 Degree CNC Drilling Tool Coated Solid Carbide for Metal Alloy Steel Hole BL2060

Couldn't load pickup availability

Share

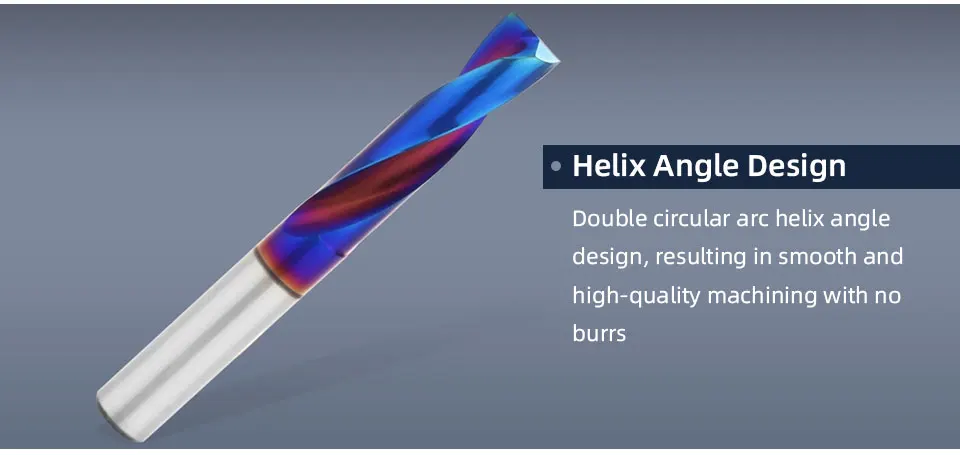

Helix Angle Design

Double circular arc helix angle design, resulting in smooth and high-quality machining with no burrs

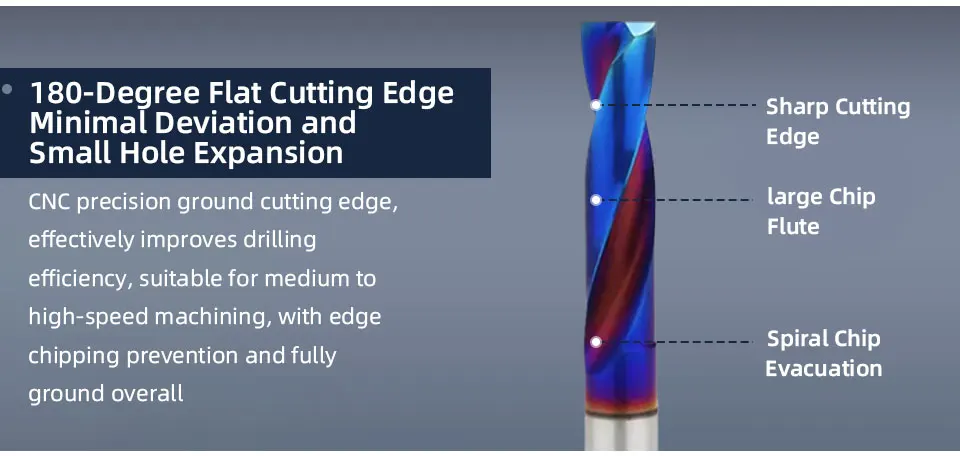

180-Degree Flat Cutting

CNC precision ground cutting edge, effectively improves drilling efficiency, suitable for medium to high-speed machining, with edge chipping prevention and fully ground overall

Sharp Cutting Edge

large Chip Flute

Spiral Chip Evacuation

Surface industrial-grade wear-resistant coating with strong versatility, capable of machining various types of die steel, cast iron, copper parts, etc

Universal Round shank Standard Chamfer

Tail anti-slip design, close to the chuck, holds tighter without slipping

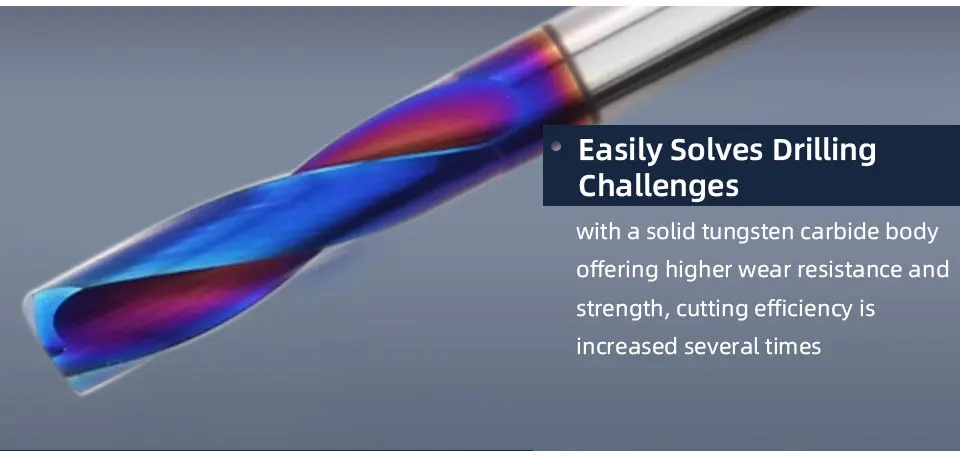

Easily Solves Drilling Challenges

with a solid tungsten carbide body offering higher wear resistance and strength, cutting efficiency is increased several times

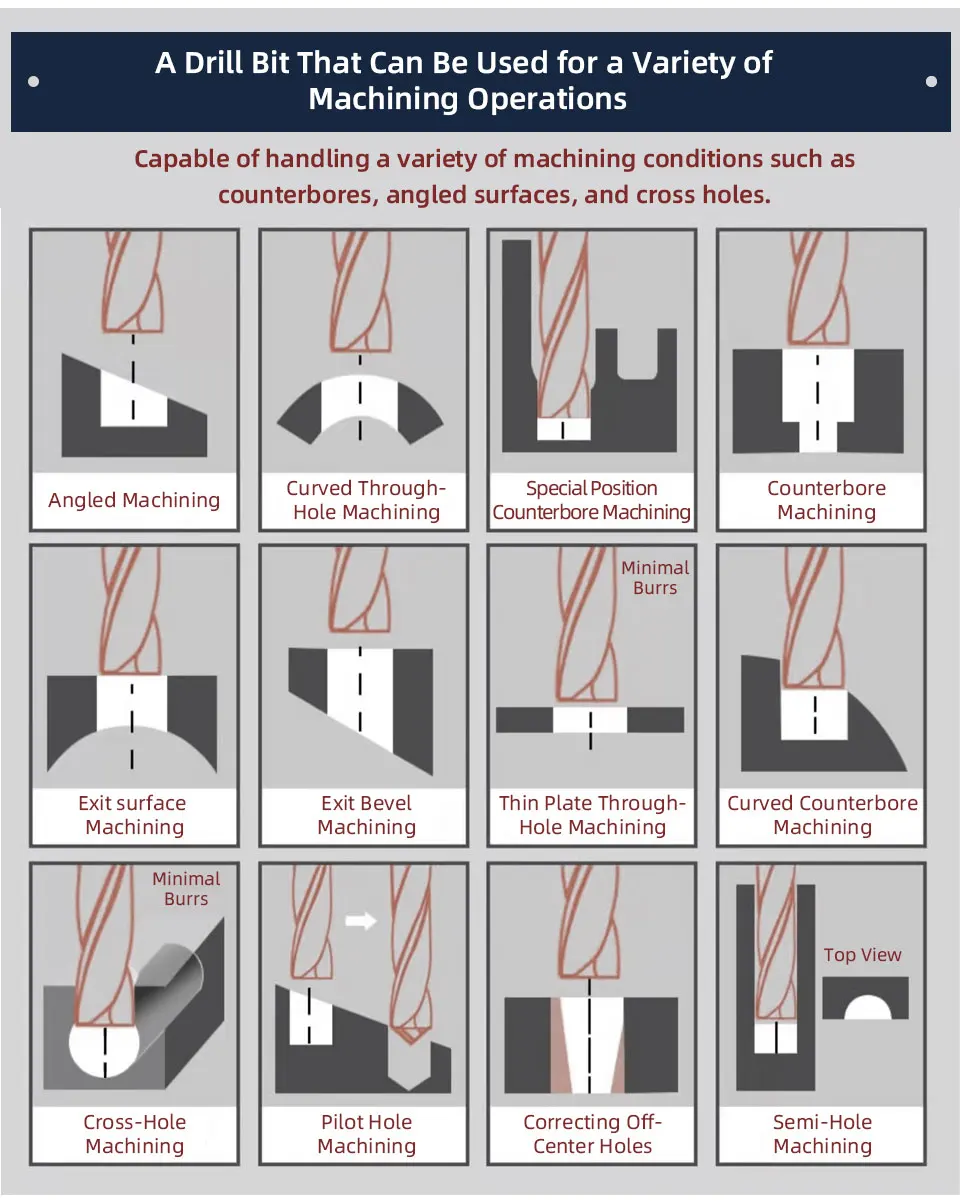

A Drill Bit That Can Be Used for a Variety of Machining Operations

Capable of handling a variety of machining conditions such as counterbores, angled surfaces, and cross holes.

Angled Machining

Curved Through-Hole Machining

Special Position Counterbore Machining

Counterbore Machining

Exit surface Machining

Exit Bevel Machining

Thin Plate Through- Hole Machining

Curved Counterbore Machining

Cross-Hole Machining

Pilot Hole Machining

Correcting Off-Center Holes

Semi-Hole Machining

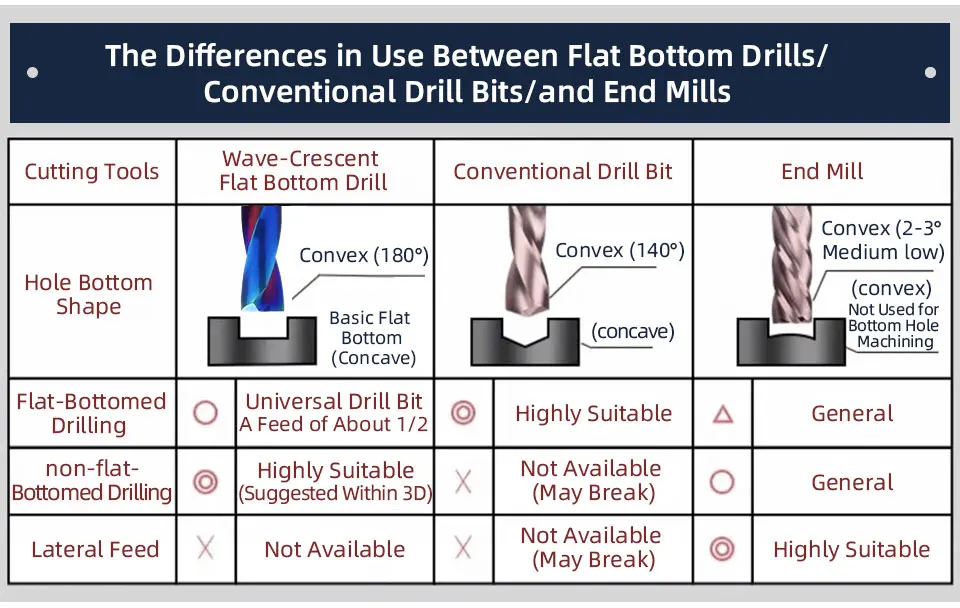

The Differences in Use Between Flat Bottom Drills/ Conventional Drill Bits/and End Mills

Cutting Tools:

Hole Bottom Shape

Flat-Bottomed Drilling

non-flat-Bottomed Drilling

Lateral Feed

Wave-Crescent Flat Bottom Drill:

Convex (180°) 、Basic Flat Bottom (Concave)

Universal Drill Bit A Feed of About 1/2

Highly Suitable (Suggested Within 3D)

Not Available

Conventional Drill Bit:

Convex (140°)、 (concave)

Highly Suitable

Not Available (May Break)

End Mill:

Convex (2-3° Medium low)、(convex)、Not Used for Bottom Hole Machining

General

Highly Suitable

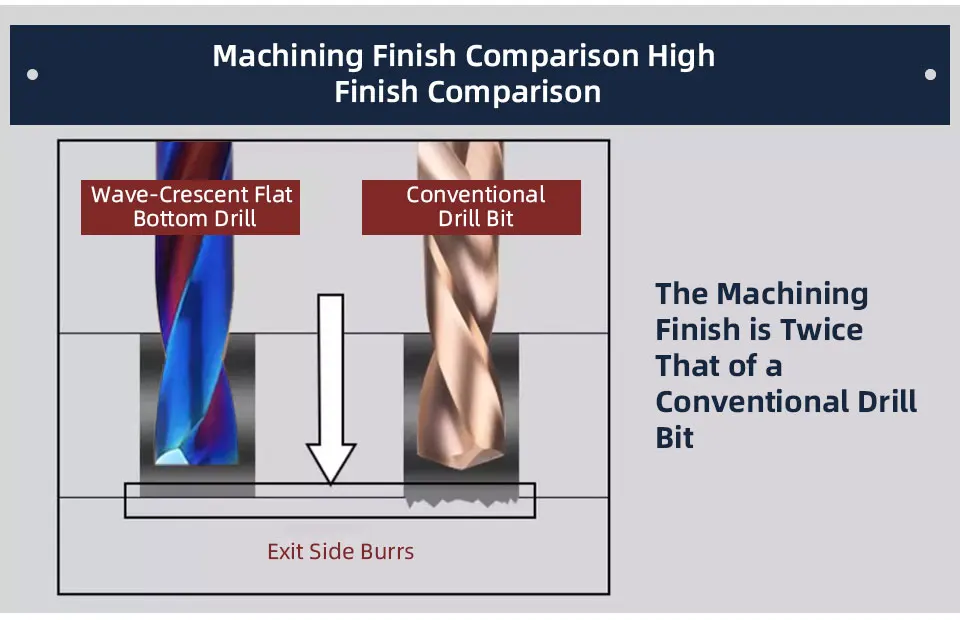

Machining Finish Comparison High Finish Comparison

The Machining Finish is Twice That of a Conventional Drill Bit

Wave-Crescent Flat Bottom Drill

Conventional Drill Bit

Exit Side Burrs

Flat Bottom Drill Bit

A flat bottom drill bit is a tool used for drilling holes, characterized by a flat bottom, which provides better positioning and stability during drilling. Flat bottom drill bits are commonly used in metalworking, woodworking, and plastic processing industries, and are suitable for applications that require high-precision hole locations.

Material

Flat bottom drill bits are typically made from carbide materials , to ensure the hardness and wear resistance of the drill bit.

Shape

The cutting edge of the flat bottom drill bit is designed with sharp cutting edges, with a sharp point at the center for centering.

Use

Flat bottom drill bits are suitable for drilling various materials, especially in metalworking where precise hole locations are required. They are often used for creating hinge holes, screw holes, etc.

Usage Method

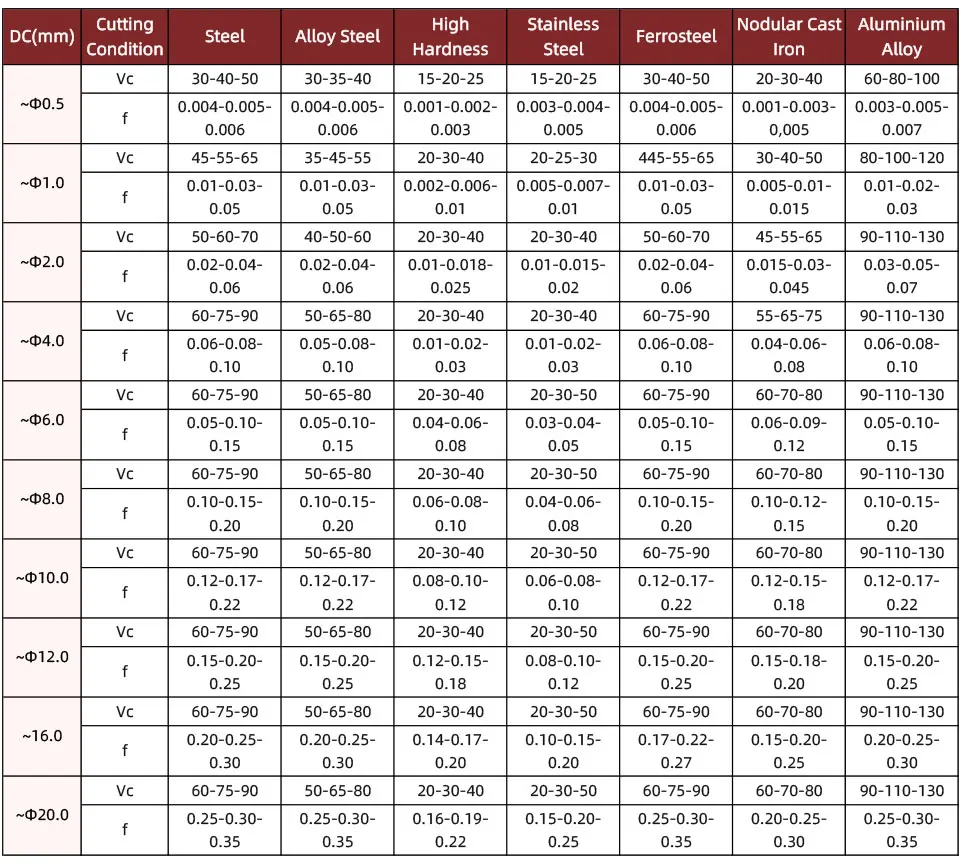

When using a flat bottom drill bit, it is usually necessary to pre-drill a pilot hole with a center drill to ensure the drill bit can be accurately positioned when starting to drill. The rotational speed and feed rate of the drill bit need to be adjusted according to the material type and drill bit size.

Flat bottom drill bits are commonly used tools in manufacturing and handicraft industries. Correct selection and use of flat bottom drill bits can improve work efficiency and processing precision.