BB Tools

BB Dovetail Milling Cutter-BB2055

BB Dovetail Milling Cutter-BB2055

Couldn't load pickup availability

Share

BB Dovetail Cutter Series BB燕尾槽铣刀系列

Precise Choices for Different Machining Needs

为不同加工需求提供精准选择

BB brand dovetail cutters are designed for machining high-precision dovetail slots, guides, and mold tapered edges. We offer three series to meet all needs

BB品牌燕尾槽铣刀专为加工高精度燕尾槽、导轨及模具斜边而设计。我们提供三大系列,满足从全方位需求。

直槽系列 BB2055-Straight

Excellent rigidity, large chip space, cost-effective 刚性极佳,容屑空间大,成本效益高General purpose, non-ferrous metals, short-chip materials, routine maintenance通用加工,有色金属,短切屑材料

螺旋槽系列BB2055-Spiral

Smooth cutting, efficient chip evacuation, superior surface finish 切削轻快,排屑顺畅,表面光洁度更高 Steel, stainless steel (long-chip materials), deep slot machining, high surface finish requirements钢件、不锈钢长屑材料,深槽加工,高表面要求

Economy Series 经济款系列BB2050-E

Highly competitive price, meets basic functional needs价格极具竞争力,满足基本功能需求, Low-frequency machining, budget-sensitive projects, education, and simple repairs低频次加工,预算敏感型项目,教学及简易维修

BB2055-直槽系列 - 注重刚性

-

Geometry: Zero helix angle straight flute, ensuring maximum edge strength and impact resistance.

-

几何设计:零螺旋角直槽,确保最大的刃口强度和抗冲击性。

-

Chip Evacuation: Vertical chip ejection, ideal for brittle materials like cast iron, prevents chip wrapping.

-

排屑方式:垂直排屑,适合加工铸铁等脆性材料,避免屑末缠绕。

-

Advantages:

-

优势:

-

Highest rigidity due to no helix angle, ensuring extreme machining stability.

-

无螺旋角,刚性最强,加工稳定性极高。

-

Large chip gullet, suitable for larger depth of cut within the groove.

-

大容屑槽,适合在沟槽内进行较大切深的加工。

-

-

Recommended For: Dovetail machining of common steel, cast iron, and aluminum bronze.

-

推荐使用:普通钢、铸铁、铝青铜的燕尾槽加工。

BB2055-螺旋槽系列 - 高效之选

-

Chip Evacuation: Helical flutes smoothly evacuate chips upwards, effectively protecting the machined surface.

-

排屑方式: 螺旋槽将切屑沿容屑槽向上平稳排出,有效保护已加工表面。

-

Advantages:

-

优势:

-

Smoother cutting process, significantly reduces vibration, extends tool life.

-

切削过程更平稳,显著减少振动,延长刀具寿命。

-

Excellent chip evacuation, ideal for deep cavities and long-chip materials (e.g., steel, stainless steel).

-

出色的排屑能力,非常适合深腔、长切屑材料(如钢、不锈钢)的加工。

BB2050-E经济款系列 - 性价比标杆

-

Geometry: Basic design based on straight angle, optimized for production cost.

-

几何设计: 基于直槽基础设计,优化生产成本。

-

Material & Process: Cost-optimized materials and manufacturing processes ensure core functionality.

-

材料与工艺: 采用成本优化的材料与制造工艺,确保核心功能。

-

Advantages:

-

优势:

-

Highly attractive price, ideal for projects with limited budgets.

-

极具吸引力的价格,是预算有限项目的理想选择。

-

Covers the most common applications with standard dovetail angles and sizes.

-

提供标准的燕尾角度和尺寸,覆盖最常用的应用需求。

-

-

Recommended For: Maintenance, Repair, Overhaul (MRO) projects, low-frequency production, education, and training.

-

推荐使用: 维护、修理、操作(MRO)项目、低频次生产、教育培训。

-

-

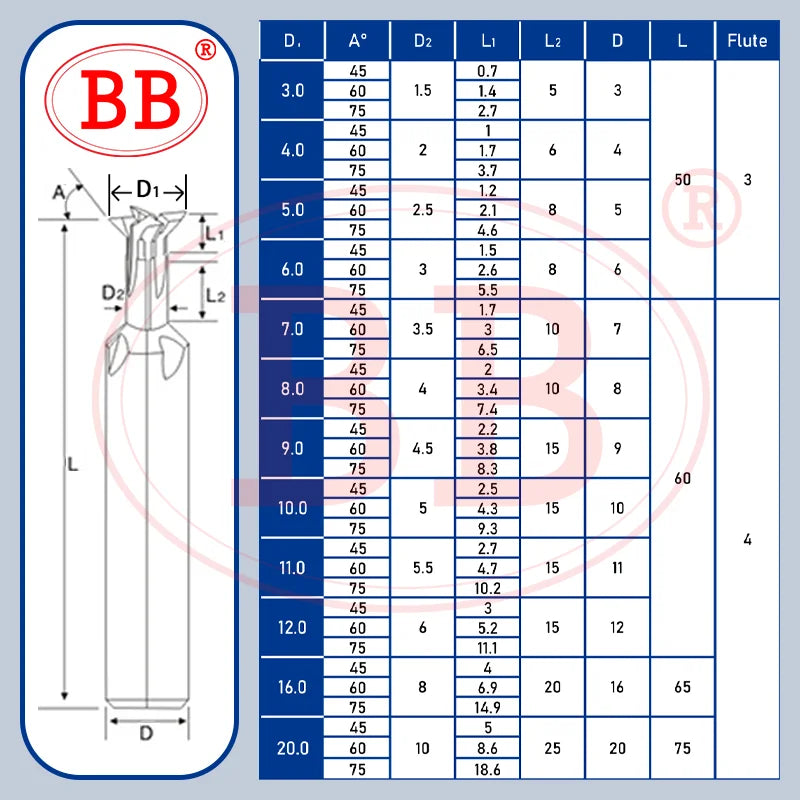

Technical Specifications

技术规格

-

Common Angles: 30°, 45°, 60°, 75° (Customizable per client requirements)

-

常用角度: 30°,45°,60°,75° (可根据客户需求定制)

-

Tool Material: Solid Carbide 刀具材质: 整体硬质合金

-

Coating Options: Coatings available to enhance performance

-

涂层选项: 可提供涂层以提升性能

Applicable Ranges

☆ Suitable materials and mechanical equipment for cutter.