BB Tool

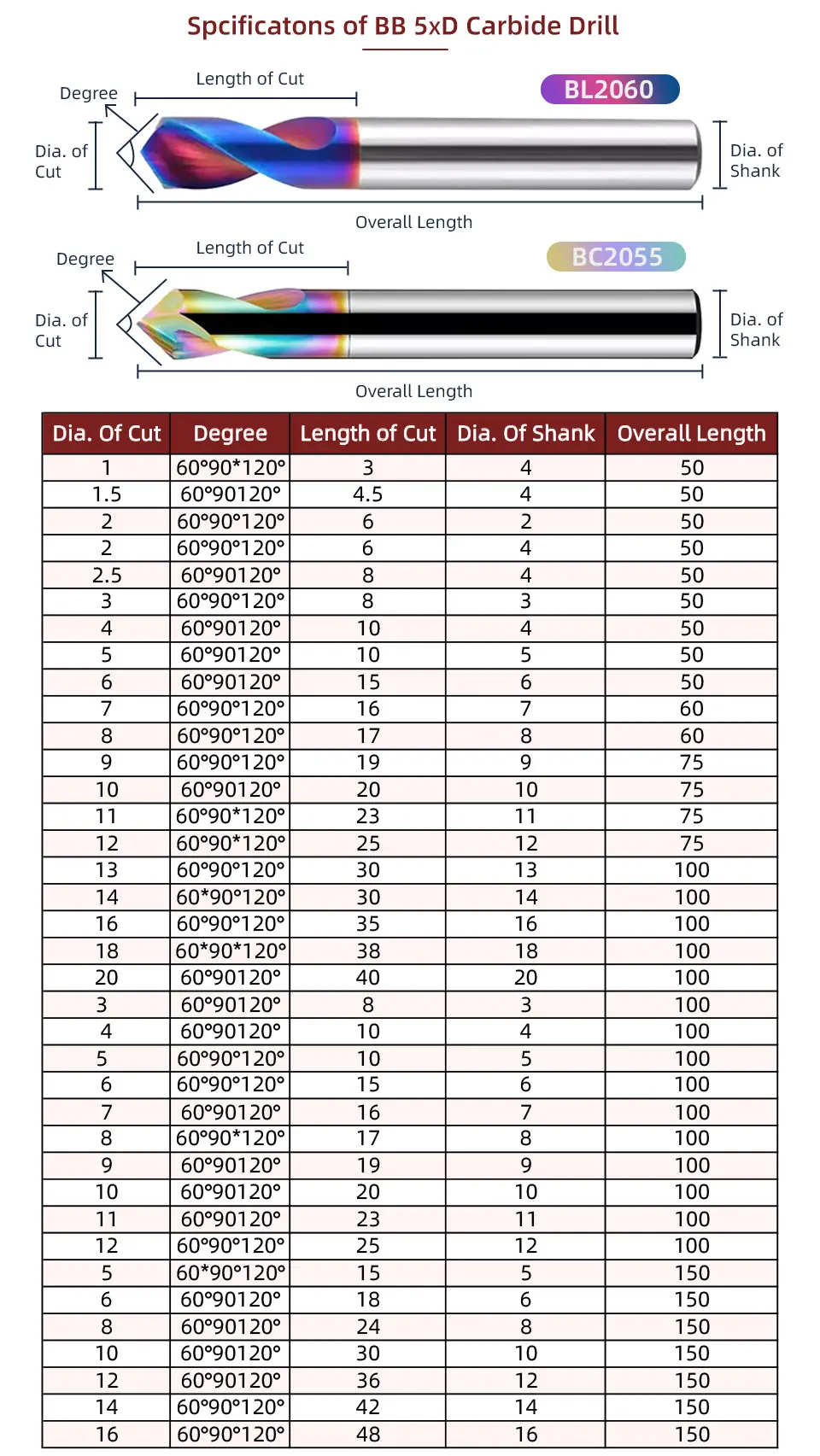

BB Spot Drill Bit CNC Hole Making Tool NC 60 90 120 Degree Short Drill 1mm-20mm Hard Steel Aluminum Coating BL2060 BC2055

BB Spot Drill Bit CNC Hole Making Tool NC 60 90 120 Degree Short Drill 1mm-20mm Hard Steel Aluminum Coating BL2060 BC2055

Couldn't load pickup availability

Share

BB Spot Drill-BL2060

BL2060- For iron, steel

BC2055-For aluminum ,nonferrous metals

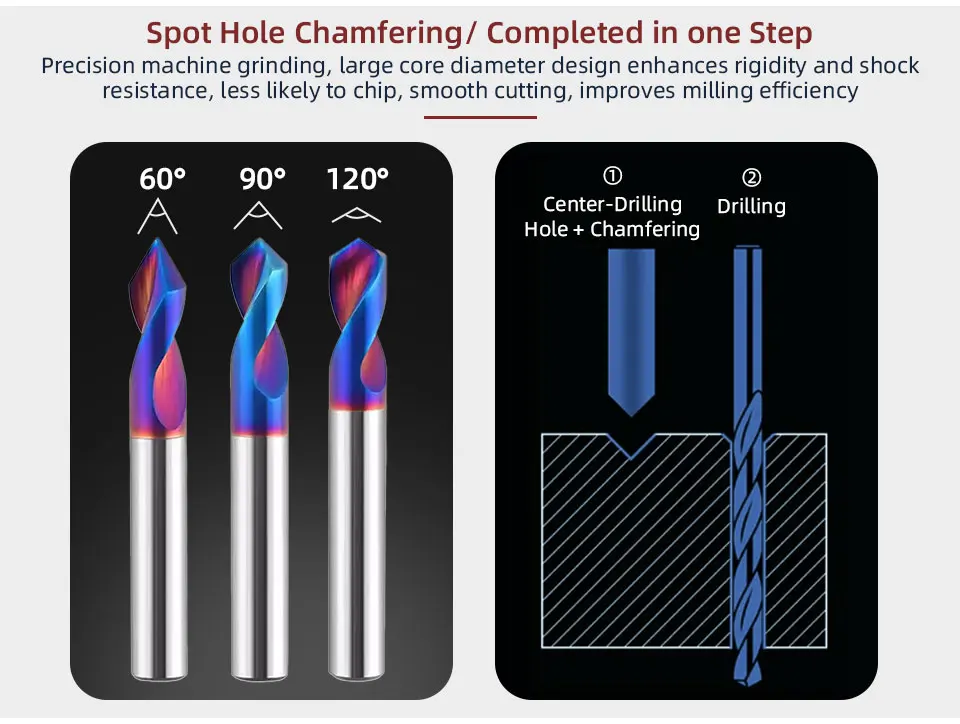

Spot Hole Chamfering/ Completed in one Step

Precision machine grinding, large core diameter design enhances rigidity and shock resistance, less likely to chip, smooth cutting, improves milling efficiency

①Center-Drilling Hole + Chamfering

②Drilling

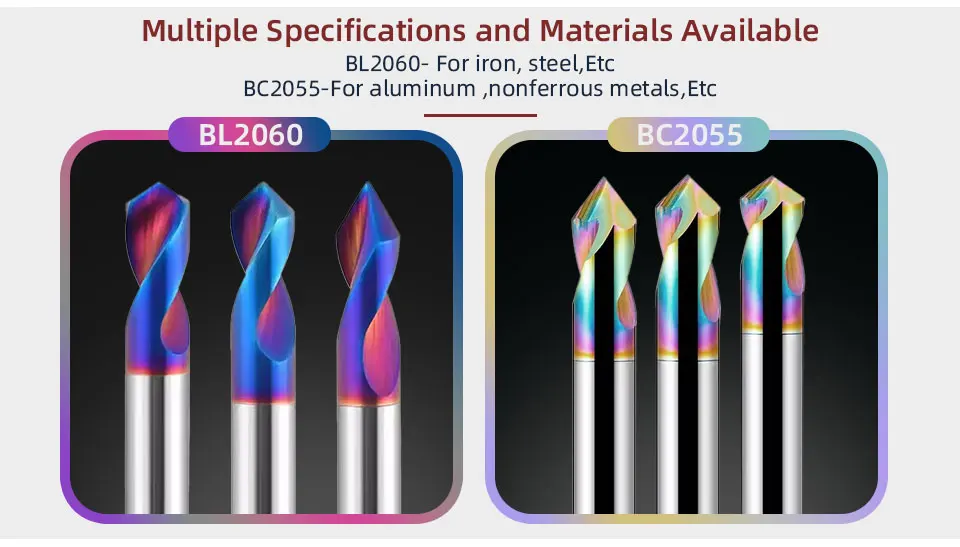

Multiple Specifications and Materials Available

BL2060- For iron, steel,Etc

BC2055-For aluminum ,nonferrous metals,Etc

For More Convenient, Faster, and More Efficient use when Paired Together

Can be Used With ER Collet Chuck

Can be Used With ER Collet

Note: Accessories are available in our store, please contact customer service

Selected High-Quality Carbide Material

Wear-resistant and durable, anti-wear

Wide Chip Disposal Groove Design

Chip evacuation is smooth, reducing burrs

Sharp Cutting Edge Nano-Coated Blade

precise positioning, glossy surface

Optimized Handle for Stable Clamping

Easy to machine and hold, convenient to operate

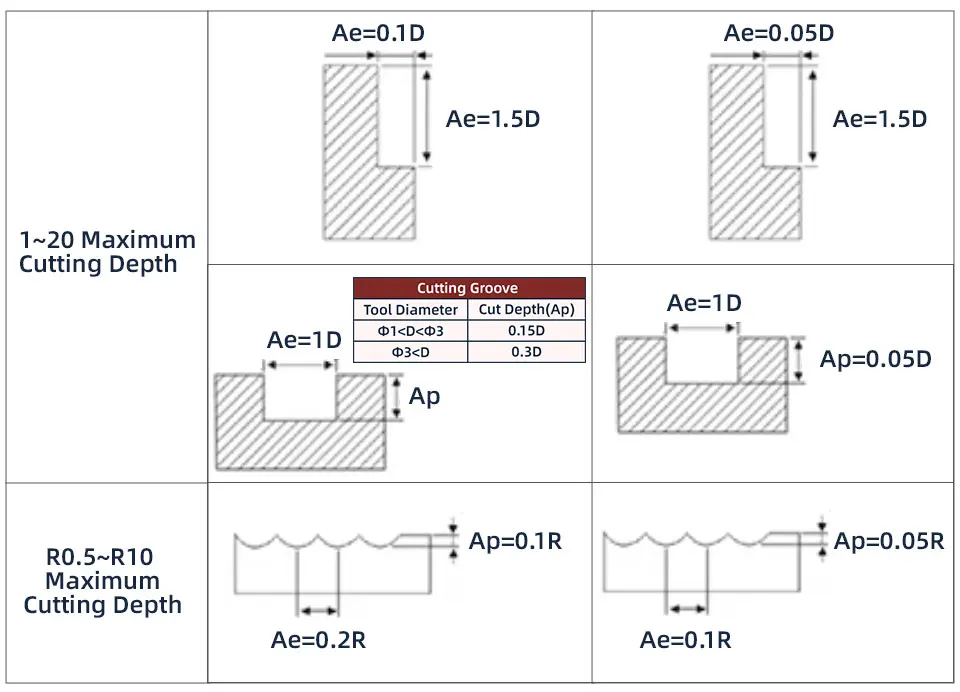

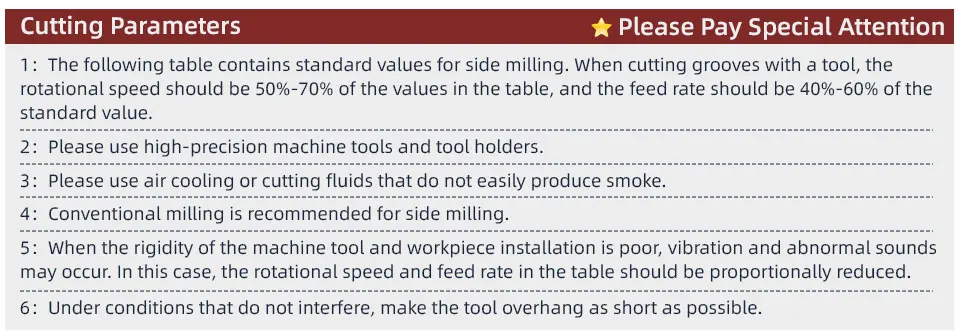

Cutting Parameters

★ Please pay special attention:

1:The following table contains standard values for side milling. When cutting grooves with a tool, the rotational speed should be 50%-70% of the values in the table, and the feed rate should be 40%-60% of the standard value.

2:Please use high-precision machine tools and tool holders.

3:Please use air cooling or cutting fluids that do not easily produce smoke.

4:Conventional milling is recommended for side milling.

5:When the rigidity of the machine tool and workpiece installation is poor, vibration and abnormal sounds may occur. In this case, the rotational speed and feed rate in the table should be proportionally reduced.

6:Under conditions that do not interfere, make the tool overhang as short as possible.